Getting to Know Ultra-fine Surface Finish - 5G Technology

Within the mold manufacturing industry, you might have heard “Mirror Surface Finish” which means a manufacturing process to produce a smooth, highly shining surface product, providing a reflection quality of a mirror. However, not all materials can be produced with such highly shining quality, for instance, the medium carbon steel (S45C, S50C) or the material with low nickel-chromium steel of which the material quality cannot be shining. On the other hand, the steel and mold steel P20 such as STAVAX or materials with high nickel-chromium steel can be produced with highly shining quality.

However, the details and methods are still limited within a small group. “Mirror Surface Finish” is the surface quality at “Ultra-fine Surface Finish” level.

M Report News Agency will delve into this with Mr. Boonsom Korpraserttavorn, the JINGDIAO leader at Machine Tech Co., Ltd. who has over 30 years of experience in machinery for mold manufacturing.

What is Ultra-fine Surface Finish?

Nano Surface Finish Machining

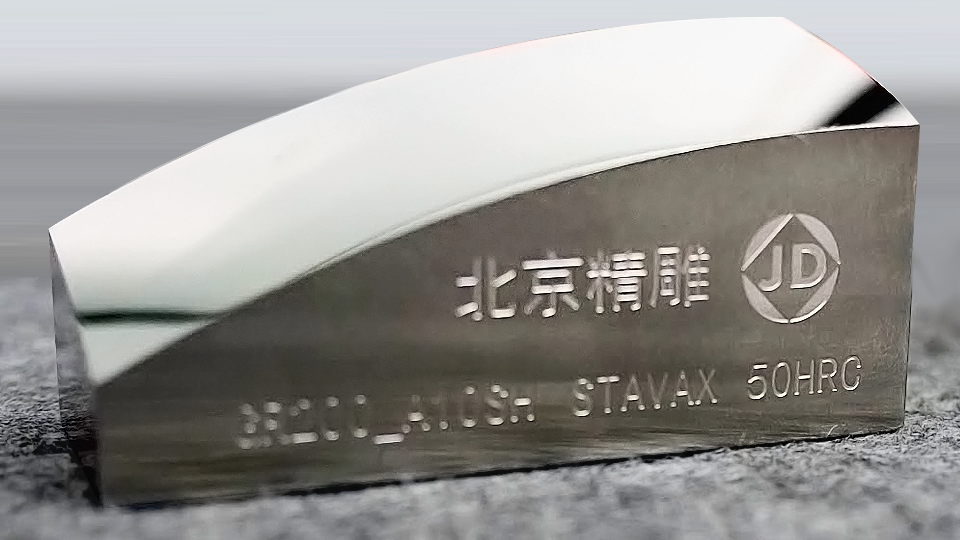

Machine : JDGR200_A10SH

Material : STAVAX (HRc 50)

Dimension : 75 x 30 x 40 mm.

Finishing Cutter : D2 R1 (PCD Cutter)

Finishing Time : 12 hour 45 minute

0.1 μm Feeding, 1.0 μm Grooving

“Ultra-fine Surface Finish is the shining surface with ultra-fine finishing at 0.025 Ra µm or is called Super Finishing, also widely known as Mirror Surface Finish.”

Finished products that require ultra-fine surface finish mold to create excellent surface quality are found in many industries for example, in the automobile industry – a headlamp requires highly precise production quality, especially the “headlight reflector” which directs the random light rays of the light bulb into a concentrated beam of light with suitable reflection without going into other drivers or pedestrians.

LED Reflector Mold

Machine : JDGR200-A10H

Material : S136 (HRc 52)

Dimension : 30 x 30 mm.

Finishing Cutter : PCD D2 R1

Finishing Time : 2 hour 23 minute

Typical Point : No polishing or Lapping allow

As for the electronics industry which includes such products as smartphones, cameras, LED screens, and others, many parts also require excellent quality of surface finish such as camera lens and smartphone body with curved design. In addition, the excellent quality of surface finish is also needed in producing prosthesis in the medical devices industry, jewelry parts in the jewelry industry, and toy models in the toy industry.

It can be said that in 5G wireless technology world, the parts manufacturers will dramatically need the manufacturing technology of Ultra-fine Surface Finish.

What are the methods for Producing Products with Ultra-Fine Surface Finish?

Method 1: The ultra-fine surface finish is usually performed after the production of the product is completed. In general, it is a handwork made by a skillful person. Practically, the handwork polishing has many limitations, for instance, the work is too small, complex, contains many deep grooves, has small holes, etc., making it hard to be polished. Also, the form of the product, sometimes, cannot be polished by hands or other methods. In many cases, the mold manufacturers want to produce the workpiece with the exact form as CAD model data in order to avoid any distortion occurred to the mold which may cause errors to the finished work.

Method 2: Another widely known method is EDM or Electrical Discharge Machining, of which the application is required when the conventional polishing cannot be performed. However, this polishing method requires a high level of electrode and extensive time which leads to high cost. In addition, the surface finish of the EDM method is not as polished as it is performed by a milling machine.

Method 3: The surface polishing with milling machine or machining center or known as “Nano Surface Machining” requires high-quality machine to respond to a program with precision of nanometer level while the mechanism which controls the movement can respond to highly detailed orders. Also, the spindle set is very balanced and stable.

Why “ Jingdiao Premium Class Machining Center? ”

The glimpse of opportunity is suddenly brightened when Mr. Boonsom Korpraserttavorn introduced us to “0.1μ feed, 1μ cutting technology” from JINGDIAO which is an innovative technology of high-speed milling with compact structural design. The machine can steadily achieve “0.1μ feed, 1μ cutting of sub-micron level machining ability, leading to preciseness and accuracy. It is the machine to produce the finished work with specifically high-quality ultra-fine surface finish or super finishing.

“JINGDIAO” is the leading brand which has continued its business from its recognition of high-quality ultra-fine surface finish that can actually achieve carving a workpiece of actual size of “ant”. JINGDIAO is a brand under Beijing Jingdiao Group, a high-tech and innovative corporation which focuses on R&D and produces tools and CNC machining. It was founded in 1994. In 2017, the Group received the recognition of the "Top 100 Enterprises in China’s Machinery Industry.” Currently, it consists of the R&D headquarter and over 40 branches across the world. In Thailand, Machine Tech Co., Ltd. is appointed as the exclusive distributor to provide know-how technology and after-sales service.

JINGDIAO Showroom & Technical Center

@Machine Tech Co., Ltd. Suvarnabhumi Factory

Tel. +662 726 7191-5