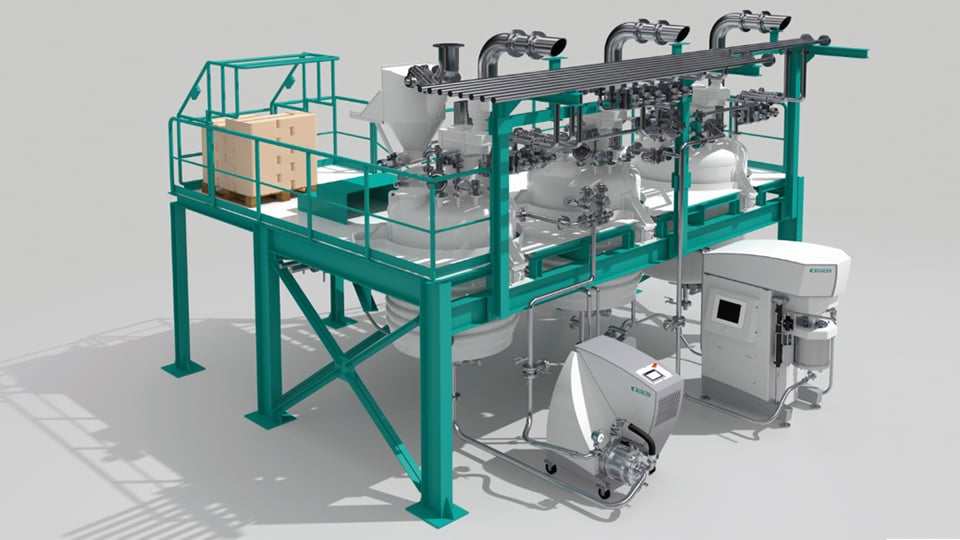

Bead Mill Machine. MacroMedia™ and Micromedia+™. The most efficient wet-grinding process for inks and surface coating material.

The compact production module, with its integrated MacroMedia™ and MicroMedia+™, offers you the most efficient wet grinding process. Thanks to the pre-designed module, the installation and commissioning time will be reduced to a minimum. This solution is perfect for cost-efficient production of inks or other demanding wet grinding tasks.

Optimal process to achieve nano to micron target particle size for product material with low viscosity. Flow rate capacity up to 4000 litres per hour.

Unbeatable top quality.

The MacroMedia™ improves the process control in the pre-dispersing stage, allowing optimization of the subsequent fine grinding process with the MicroMedia+™ bead mill. The result: higher profits and perfect quality in the shortest possible time for high-performance coatings. Solid and liquid materials are optimally dosed in the mixing tanks with a continuous transfer from the mixing tank to the recirculation tank

User-friendly control system.

3 different smart control options are available: from “Comfort” to “Premium” and “Premimum Plus”. The Comfort mode offers you the convenient solution with manual operation. Premium is the first-class solution with PLC and touchscreen while the integrated Premium Plus control system offers an intuitive design for maximum productivity and easy handling with enhanced solutions and extendable functionalities. Bühler control systems are designed for the IoT, which opens up numerous possibilities for an extended use in the future.

Smart and flexible.

The smart design of the production module is perfect for a cost-efficient and flexible production solution on the smallest possible footprint.

- Macromedia™: The revolutionary pre-dispersing solution

- Convenient operation via touchscreen panel (premium solution)

- Convenient solution with manual operation and process optimization

- Temperature monitoring

- Compact design with smallest footprint (1250x900 mm) and a height of 1400 mm.

- Process zone with a combined pump and grinding chamber

Micromedia+™: The high-performance bead mill.

- Easy handling with redesigned bearing units and lifting device

- Easy accessibility for simple maintenance

- Easy configuration for compliance with local regulations and customer needs

- Maximum energy efficiency due to smaller bead and highest power density

- Large screen surface and real centrifugal bead separation for highest flow capability

- Wide range of product sizes

More information, please contact:

Bühler (Thailand) Ltd.

Room No. 1702-1703, 17th Floor, 42 Tower

65 Soi Sukhumvit 42, Sukhumvit Road,

Prakhanong, Klongtoey, Bangkok 10110

Tel: +66 (0) 2 712 2600-1, 2570-1 ext. 123

Fax: +66 (0) 2 712 2572

Mail to: [email protected]