Prolific Group Partners with Tianhong Machinery to Advance Aluminum Alloy Casting Technology to Global Standards

As global industries shift toward manufacturing lighter yet stronger components, Prolific Group has joined forces with Jiangsu Tianhong Intelligent (TiHO)—a leading expert in aluminum alloy casting solutions—to provide end-to-end services from design to commissioning. This collaboration aims to meet the needs of modern industries seeking quality, efficiency, and sustainability in every stage of production.

Complete Aluminum Casting Solutions

Prolific Group and TiHO offer end-to-end aluminum alloy foundry solutions, covering every stage from upstream design to downstream production, including:

- Product & Mold Design: Tailoring product and mold designs to match specific manufacturing requirements.

- Process Optimization: Enhancing production efficiency through refined process control.

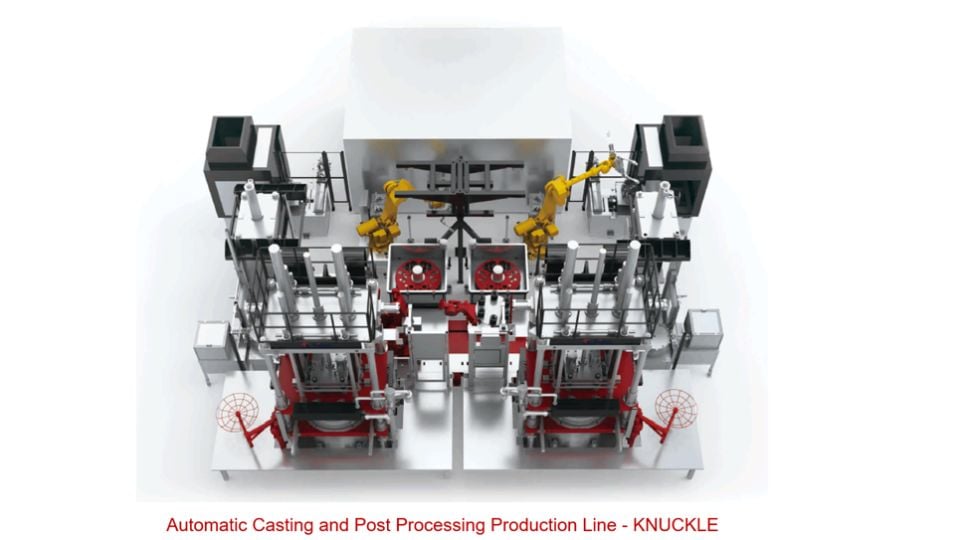

- Production Line & Automation: Designing automated production lines that integrate IoT and smart control systems.

This integrated approach ensures greater precision, reduced waste, and consistent product quality throughout the entire casting process.

Expertise in Automotive and EV Applications

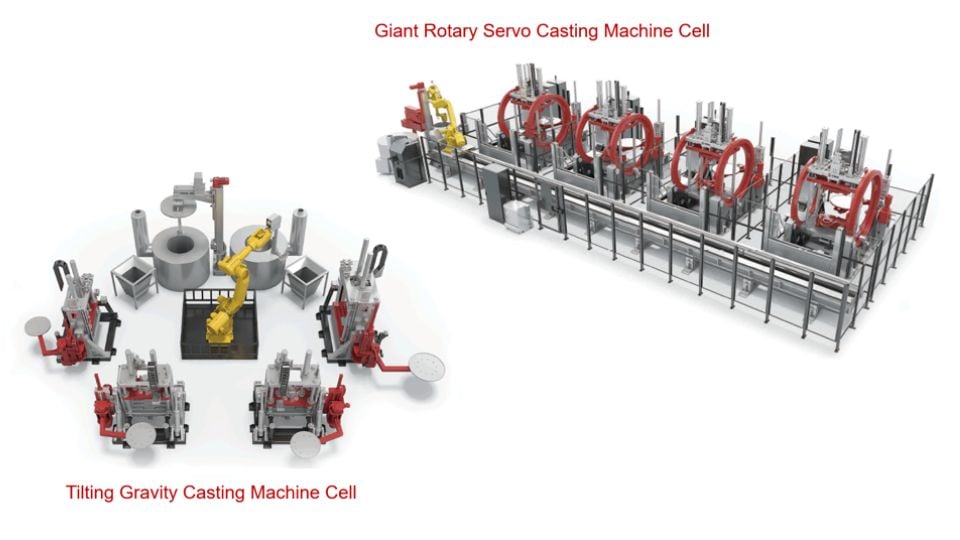

TiHO specializes in automotive and electric vehicle (EV) component production, leveraging advanced casting technologies such as:

- Low Pressure Die Casting (LPDC)

- Gravity Die Casting (GDC)

The company manufactures key components including:

- Cylinder Heads and Cylinder Blocks

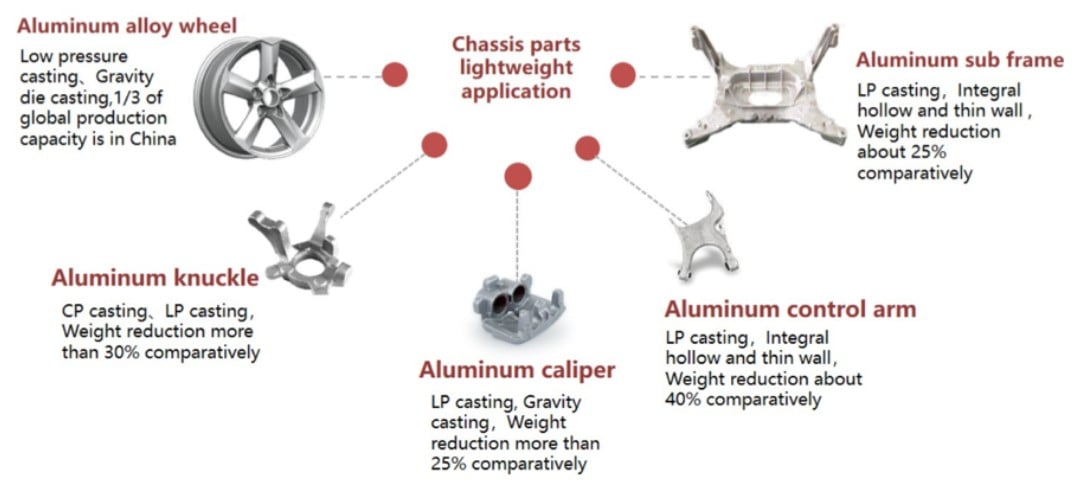

- Chassis and Suspension Components

- Alloy Wheels, Brake Systems, and Powertrain Parts

- EV Motor Housings and Battery Trays

TiHO’s strength lies in combining high strength, precision, and lightweight performance, aligning with the global trend toward lightweight manufacturing for energy efficiency and sustainability.

Smart Manufacturing and Automation

With its Smart Foundry Technology, TiHO enables real-time quality monitoring and full process traceability, ensuring superior control and product consistency.

Intelligent Solution – Management Billboard Traceability and Process information

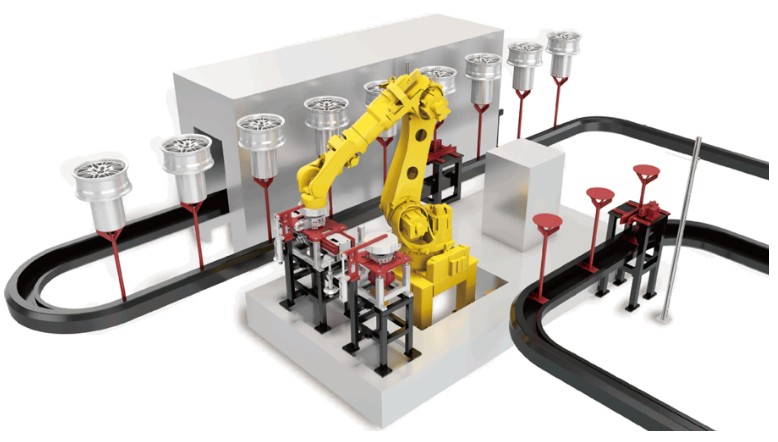

In secondary processes such as painting or surface finishing, the integration of robotic automation further enhances precision, reduces human error, and minimizes labor dependency—paving the way for smarter and more efficient production lines.

Robotic Transfer for Painting Line By adopting the innovative technologies and Robot system integration

Prolific Group’s Regional Network

As a leading provider of industrial heating systems and metal melting furnaces, Prolific Group has established a strong service network across Thailand, Vietnam, Indonesia, Singapore, and Malaysia.

The collaboration with TiHO reinforces Prolific Group’s position as a total industrial solution provider, capable of delivering excellence in energy efficiency, performance, and production quality for manufacturers in the region.

Driving the Future of Lightweight Manufacturing

The partnership between Prolific Group and Tianhong Machinery (TiHO) represents a shared vision to propel the aluminum casting industry toward a new era of Smart, Sustainable, and Efficient Manufacturing.

Together, they are setting a new benchmark for precision, energy-saving, and eco-friendly aluminum component production, supporting the global shift toward greener mobility and advanced manufacturing.

Contact Information

Prolific Heating International Co., Ltd.

11/11 Moo 11, Kingkaew Rd., Rachathava, Bangplee, Samutprakarn 10540, Thailand

📞 Tel: +66 21 708 171

📧 Email: [email protected]

🌐 Website: https://phiheating.com/

🔗 Learn more about our solutions:

👉 https://phiheating.com/th/tianhong-machinery-casting-high-quality-products/