OLYMPUS CIX100 Turnkey Technical Cleanliness Inspection System

The OLYMPUS CIX100 inspection system is a dedicated, turnkey solution for manufacturers who maintain the high quality standards for the cleanliness of manufactured components. Quickly acquire, process, and document technical cleanliness inspection data to comply with company and international standards. The system’s intuitive software guides users through each step of the process so even novice operators can acquire cleanliness data quickly and easily.

OLYMPUS CIX100 Turnkey Technical Cleanliness Inspection System: Simplify Your Technical Cleanliness

The cleanliness of components and parts is at the center of the manufacturing process. Meeting high standards for counting, analyzing, and classifying the often micron-sized contaminant and foreign particles is important for all processes: development, manufacturing, production, and quality control of the final product. International and national directives describe the methods and documentation requirements for determining particle contamination on essential machined parts since these particles directly impact the lifespan of parts and components. Previously, the mass of residue particles was used to characterize the residue. The standards in use today demand more detailed information about the nature of the contamination such as the number of particles, particle size distribution, and particle characteristic.

The OLYMPUS CIX100 Cleanliness Inspection System is designed to meet the cleanliness requirements of modern industry and national and international directives.

Standard Process for Cleanliness Inspection: Preparation and Investigation

01:Extraction, 02:Filtration, 03:Weighing, 04:Inspection, 05:Review, 06:Results

Simple and Reliable

Seamlessly integrated hardware and software result in a durable, high-throughput system that delivers reliable and accurate data.

- Easy Setup for True Turnkey Functionality

- Accurate repeatability and best secure by invariant system setup

- Excellent optical performance and reproducible imaging conditions

- Convinced durability by reproducible positioning and integrated calibration device

- Full system integration for high performance

Intuitive Guidance for Maximum Productivity

Dedicated, easy-to-use workflows minimize user action and provide reliable data - independent of the operator and experience level.

- Step-by-step guidance to improve productivity and reduce inspection and process time

- User right management to restrict functionality and avoid operator handling errors by restricting functionality

- Touch screen support for efficient operator handling

- Compliant One-Click Reporting for direct documentation

- Data Management by automated results storing and sharing options

Fast Live Analysis

The unique all-in-one-scan solution enables scans to be completed twice as fast as classical method(Inspector series). Counted and sorted particles are displayed live while powerful, easy-to-use tools make it easy to revise inspection data.

- Overview image for direct identification of filter coverage, particle clustering or worst particles

- Automatic live processing and classification of contaminant particles ranging from 2.5 µm up to 42 mm

- High Throughput by unique all-in-one-scan technology for detection of both reflective and non-reflective objects in one scan

- Live analytics and result display for shortest reaction time

- Compliant results by support of international standards

Efficient Data Evaluation

Powerful and easy-to-use tools support to revise inspection data. High flexibility is provided by support of all international standards. Clear representation of all relevant inspection results in a maximum time saving.

- Clear arrangement of images and data for efficient data review

- Visualization of different particle views for immediate identification

- Convinced capability as particle location and thumbnails linked with their dimensional images

- Easy reclassification, review revision and recalculation of inspection data

- Short reaction time by live display of overall cleanliness code, particle and classification tables

- Trend analysis to identify potential measurement deviation over the time

- Full control by displaying complete inspection data set in one view

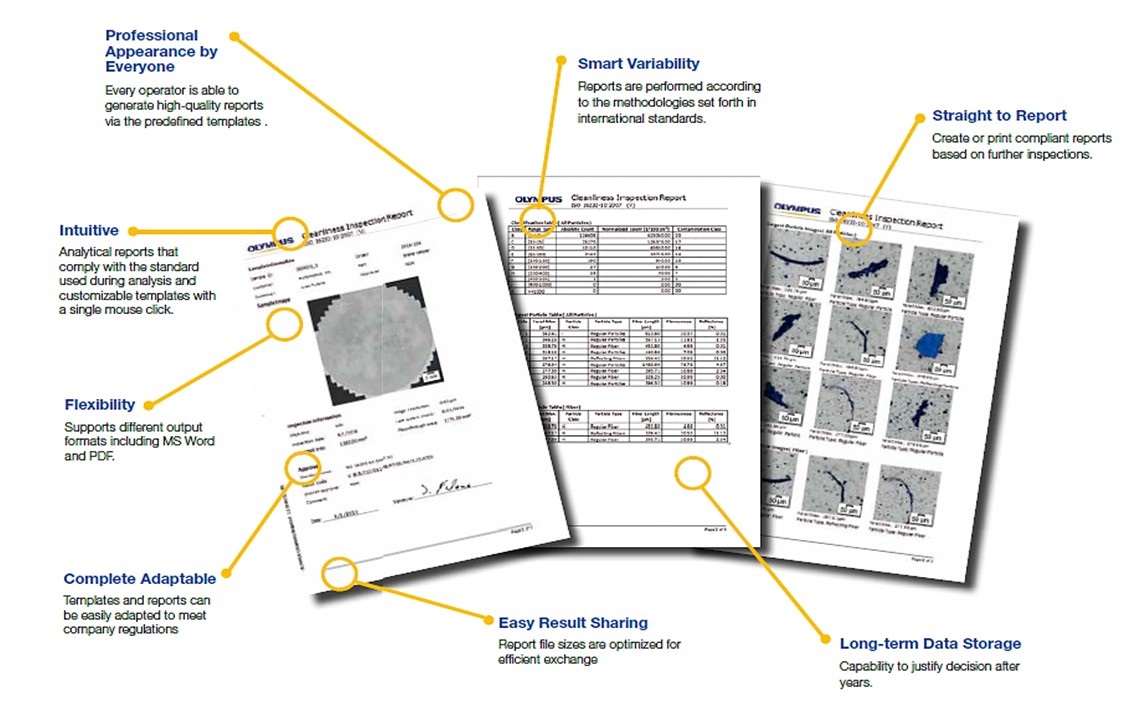

Compliant Report Creation

One-click reporting meets the requirements and methodologies set forth in international standards.

- Completely intuitive and professional documentation based on compliant templates

- Smart variability by customer adaptable templates

- Utmost flexibility by support of various output formats

- Efficient and time-optimized exchange by direct file sharing options

- Sophisticated data storage options for long-term justification of results

More information, please contact:

Quality Report Co., Ltd.

390 Soi Yothin Pattana, Praditmanootham Rd. Kwang Klongchan, Khet Bangkapi, Bangkok, 10230

Tel : 02 946 9988

Email : donrudee@qualityreport.co.th

http://www.qualityreport.co.th