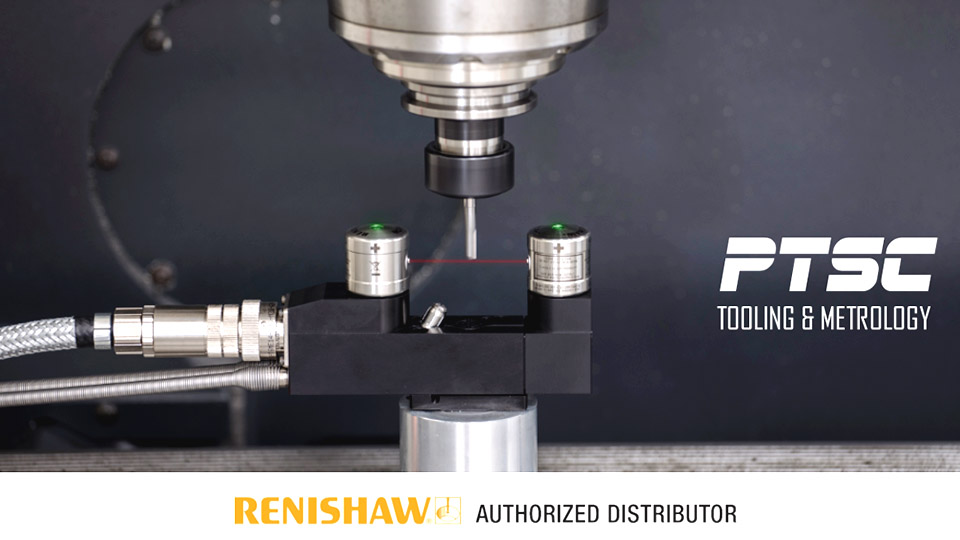

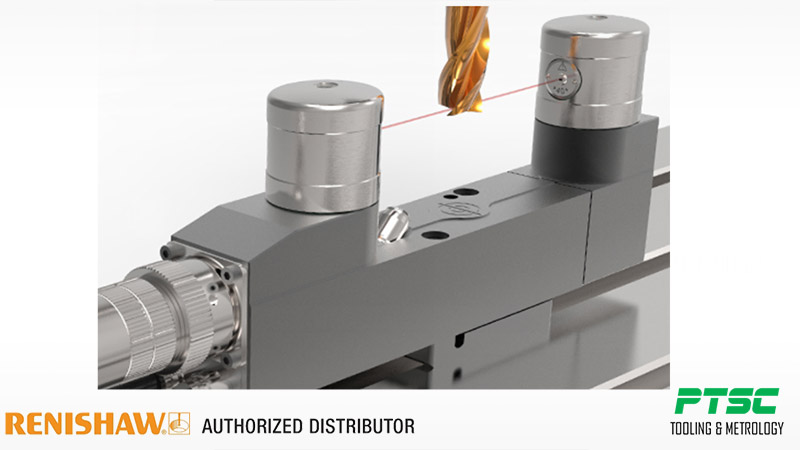

Renishaw NC4 non-contact laser tool setter

Renishaw NC4 is a high-precision, high-speed, non-contact tool measuring and broken tool detection on all sizes of vertical and horizontal machining centres, multi-tasking machines and all gantry machining centres.

Non-contact tool setting systems can reduce tool setting times by up to

90% and reduce scrap caused by setting errors. Broken tool detection

cycles enable reliable unmanned machining.

Renishaw NC4 non-contact tool setter can:

- compensate for variation during the machining process

- update the machine’s controller automatically to account for actual effects, e.g. tool wear

- automatically stop the process when broken tools are detected

- reduce rework, concessions and scrap

- measure small and fragile tools without risk of incurring damage

Increase productivity

Automatic tool setting with the NC4 gives your machine tools the intelligence they need to make decisions for themselves, enabling ‘lights out' machining.

Reduce scrap

The NC4 measures and detects tools down to Ø0.03 mm and to a repeatability of ±1.0 μm (2σ) – ensuring the production of ‘right first time' parts.

Easy-to-use

Install, configure, use and maintain the NC4 with ease thanks to our comprehensive range of smartphone and on-machine apps.

Highly flexible

A host of system options and configurations makes the NC4 the most flexible non-contact tool setting solution on the market.

Reliable operation

The NC4's integrated air blast and dual measurement mode, delivers accurate and robust performance in even the harshest machining environments.

More information, please contact:

Precision Tooling Services Co., Ltd.

Tel. 02-370-4900 auto 10 lines

Email: [email protected]

Website: www.ptsc.co.th