Touch probes for machine tools from HEIDENHAIN

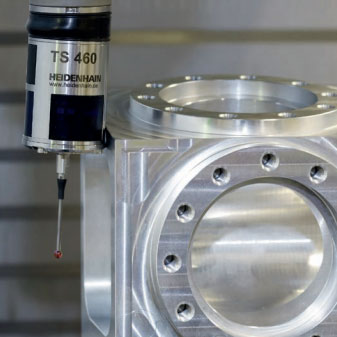

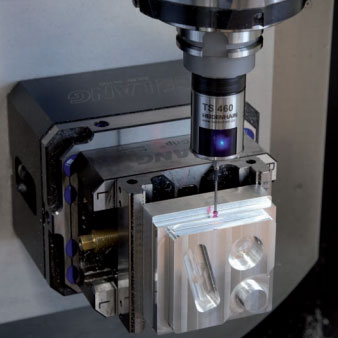

Touch probes from HEIDENHAIN are designed for use on machine tools— particularly milling machines and machining centers.

Touch probes help reduce setup times, increase machine usage time, and improve the dimensional accuracy of the finished workpieces. Setup, measuring, and monitoring functions can be performed manually or—in conjunction with most CNC controls—can be controlled by a program.

Innovative technologies

HEIDENHAIN has been developing and manufacturing touch probes for workpiece and tool measurement on machine tools for over 30 years now. It has set standards, for example, with

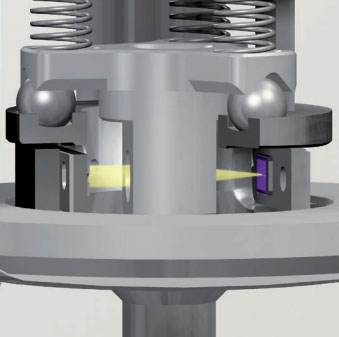

Wear-free optical sensor

Because the optical sensor is free of wear, it is able to provide the specified probing repeatability even after a large number of probe measurements (over 5 million switching cycles). This means that touch probes from HEIDENHAIN are also excellently suited for grinding machines. The optical sensor features an optimized lens system and an integrated preamplifier for stable output signals

Reliable measurement results

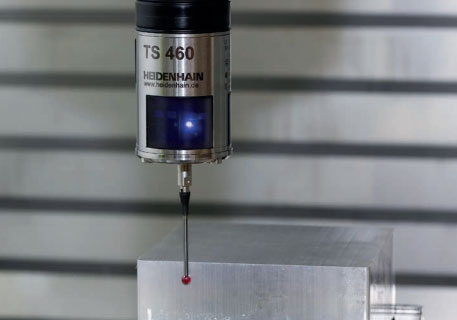

Clean measuring points are a prerequisite for high process reliability. That is why all wireless TS workpiece touch probes from HEIDENHAIN have flushers/blowers for cleaning the workpiece by means of compressed air.

Collision protection and thermal decoupling (option for TS 460)

Collision protection is a major topic at HEIDENHAIN. The touch probes feature a sizable deflection path and offer additional safety through rated breakpoints in the stylus and in the connecting pin for the probe contact. For expanded collision protection, including for the touch probe housing of the TS 460, HEIDENHAIN offers an optional mechanical adapter between the touch probe and the taper shank.

Worldwide presence

In whichever country your machine equipped with a touch probe may be found, HEIDENHAIN is there to support you on-site.

TS 460 and TT 460

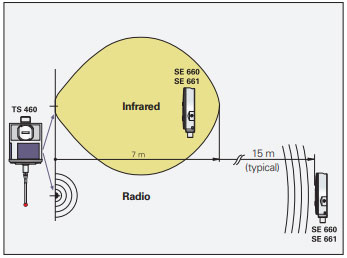

The combined signal transmission in the TS 460 and TT 460 touch probes brings together the advantages of infrared and wireless transmission into one system.

Hybrid technology: signal transmission via radio or infrared signals (only TS 460, TT 460)

The dual signal transmission of the TS 460 combines the advantages of radio signals (high range and large quantities of data) with infrared signals (ideal for fast signal transmission).

- You save time per measuring cycle without sacrificing accuracy if you activate the touch probe by radio while it is still in the tool changer Measurement is then conducted with infrared transmission, thereby enabling short transmission times

- You can operate a single touch probe version on different types of machines and on any machine size

Application examples:

Workpiece alignment

Exact workpiece alignment parallel to the axes is particularly important for workpieces that have already been partially machined so that their existing reference surfaces are in an accurately defined position.

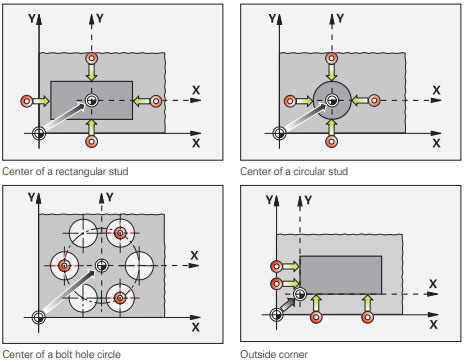

Preset setting

Programs for machining a workpiece are referenced to presets. Finding this point quickly and reliably with a workpiece touch probe reduces nonproductive time and increases machining accuracy.

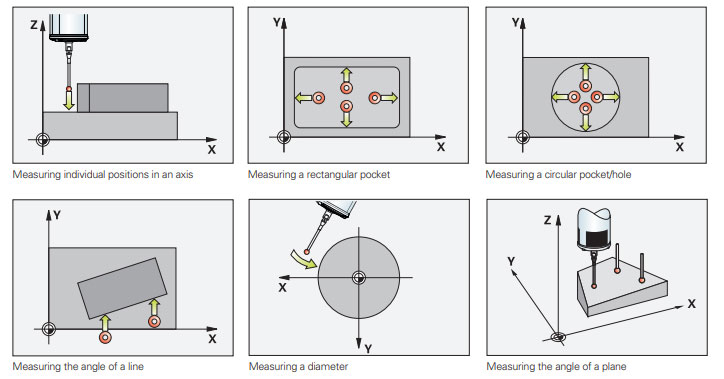

Workpiece measurement

The TS touch probes from HEIDENHAIN are suited for program-controlled workpiece measurement between two machining steps, for example. The resulting position values can be used for tool-wear compensation.

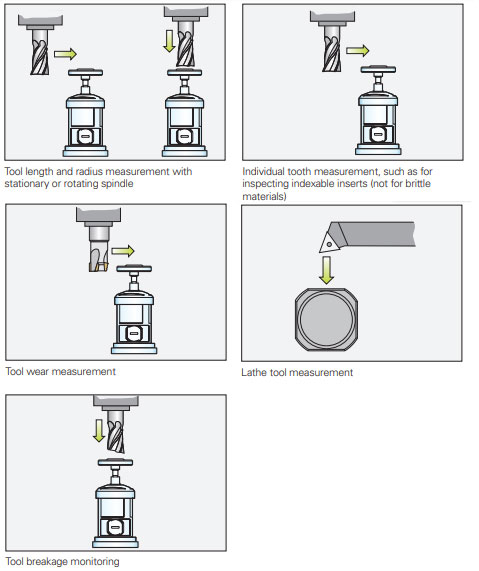

Tool measurement

Consistently high machining accuracy requires an exact measurement of tool data and cyclical inspection of tool wear. The TT tool touch probes can measure a wide variety of tools right on the machine. For milling cutters, length and diameter Tool measurements are measured, and it is also possible to measure individual teeth.

Inspecting and optimizing machine accuracy - Calibrating rotary axes

Accuracy requirements are becoming ever more stringent, particularly in the realm of 5-axis machining. Complex parts must be manufactured with both precision and reproducible accuracy, including over extended periods of time. With a TS touch probe and a KKH calibration sphere from HEIDENHAIN, you can calibrate the rotary axes of your machine and minimize measurement error in the machine’s kinematic description.

For more information of TS and TT touch probe please visit link as below

https://www.heidenhain.de/de_EN/products/touch-probes/

Inquiry, please contact:

HEIDENHAIN (THAILAND) LTD.

Tel: +662 747 2146, +662 747 2147, +662 396 1840

Email: [email protected]

Website: www.heidenhain.co.th