ALN800G: Large-size Wire-cut EDM. Achieving the superlative performance with High Speed & High Performance

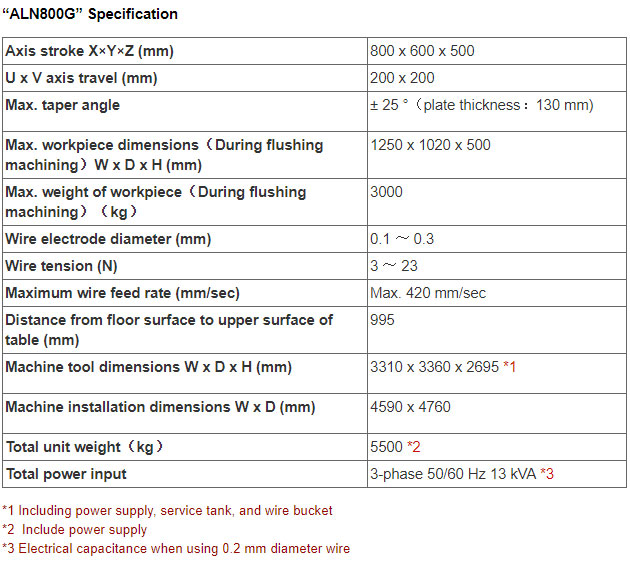

Sodick has released ALN800G, two linear motor-driven, large wire EDM (electrical discharge machining) machines that provide high speed and performance which are ideal for machining large parts and dies.

AL Series have been well received by manufacturers for precision die and part machining for products such as smartphones, tablet terminals, and precision automotive parts. ALN800G that enable machining of large workpieces, has been filled the lineup of AL Series to meet urgent demand that seek for the superior machining speed, precision, and quality of linear motor-driven wire DEM machines for a wider range of machining applications, such as for machining large dies used to manufacture automotive or electrical products, or large parts used in industries such as energy, aerospace, and automotive production.

ALN800G employs the ‘Advanced Smart Pulse’ and ‘Advanced Smart Linear’ development concepts devised for the AL Series. The two concepts also achieve high performance through several elemental technologies in areas such as the linear motor, EDM power supply, NC equipment, motion controller, and ceramics. These technologies were developed and manufactured completely in-house.

Main Features

I. 4-axis linear motor drive:

Direct drive method without a ball screw was established, utilizing a high performance linear motor developed and manufactured in-house for the 4 axes of X, Y, U and V. Precise axis movements without backlash can be maintained semi-permanently. Demonstrates accurate position control and excellent discharge characteristics while machining, through the high response and high following characteristics which are the features of the linear motor.

II. New Power Supply Unit & New Machining Circuit:

Providing the improved visibility and operability with the latest man-machine interface achieved by the 19" horizontal touch-panel. This machine is standardly equipped with the "barrel-free effect control Ⅱ" which greatly reduces the barrel amount during machining, and "TMP Control Ⅱ" which improves the surface roughness of the second cut and realizes high speed finish machining.

III. Large and Thick Workpiece Machining:

The AL800G/ALN800G supports a 500mm workpiece thickness machining standard. It is equipped with the automatic vertically sliding door, the "O-shape" work-stand, and ceramics made stand-bases. The high speed automatic wire threading unit (FJ-AWT) and the built-in 20kg wire feeder enables unattended high speed and high precision machining.

More information, please contact:

Sodick (Thailand) Co., Ltd.

บริษัท โซดิก (ประเทศไทย) จำกัด

โทร. 02-529-3925

Sales: Khun Pachara, Mobile: 081-933-9241

Email: [email protected]

website: www.sodick.co.th