CNC Double Column Machining Center “KAFO” Brand from TAIWAN

Since the establishment in 1968, KAFO (KAO FONG MACHINERY CO., LTD) keeps growth step by step along with the development of machinery industry in Taiwan based on its solid foundation of superior technology. It is not accidental that it becomes the leading brand of mold processing industry as well as faithful business partner.

The key to KAFO’s success is intensifying the know-hows, continuously improving manufacturing process, focusing on the upgrading core competency of technology and sticking to perfection. Besides, the Company has obtained the national certified endorsement, which is rated as the benchmark of the industry.

So far KAFO has accumulated its steady technological capabilities and experiences for nearly 50 years and successfully developed stable sales performances in the 8 series products of Vertical Machining Center, Double-Column Machining Center, Horizontal Machining Center, High Speed Double-Column Machining Center, Gantry Double-Column Machining Center and Drilling & Tapping Center, facilitating us in expanding global layout centered in Taiwan.

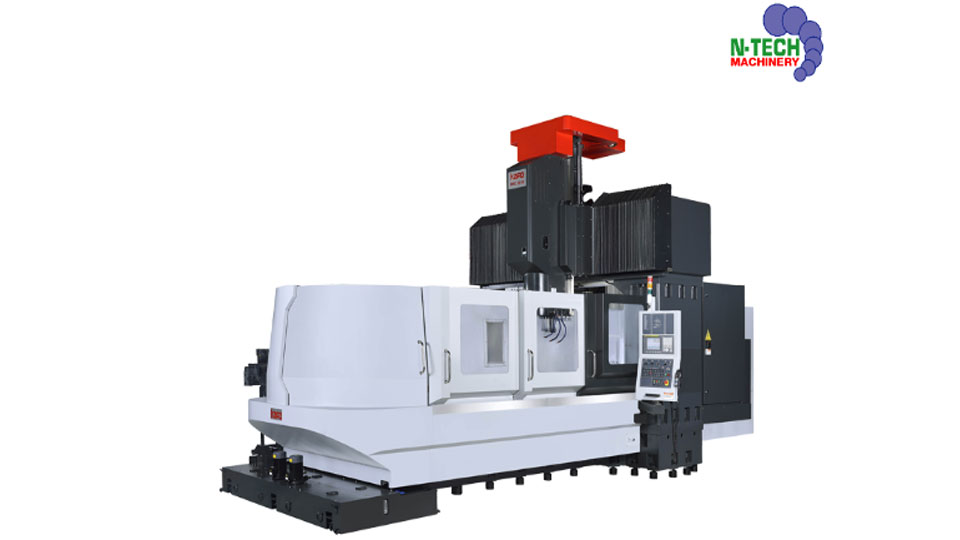

BMC Series

This series is the fix-column bridge type machining center which adopts fixed crossbeam and column, but moveable table. Applicable to all kinds of parts processing, mold processing, aluminum parts, aerospace and transportation parts processing industry etc.

KMC Series

Fixed double column machining center, with optional automatic exchange system for five-face processing machine series. Equipped with standard vertical automatic tool changer magazine tool changer magazine and can upgrade to optional vertical/horizontal magazine. Applicable to all kinds of parts processing, mold processing, aluminum parts, aerospace transportation parts processing and so on.

RV Series

Fixed double column machining center, with automatic exchange system for five-face processing machine series. Equipped with standard vertical/horizontal magazine tool and optional multi-head automatic switch system. Applicable to the demand of all kinds of parts large castings, structural parts, semiconductor cavity equipment processing, mold processing, aluminum parts, aerospace transportation parts processing needs and so on.