Double Column Grinding Machine ACC-CH-iQ Series from Okamoto

ACC-CH-iQ Series double-column grinding machine satisfies demands for high accuracy and high efficiency.

The ACC-CH-iQ Series satisfies the demands for high accuracy required for machining the progressive dies used for motor cores or LC processing, while also offering the high efficiency needed by the die base processing industry.

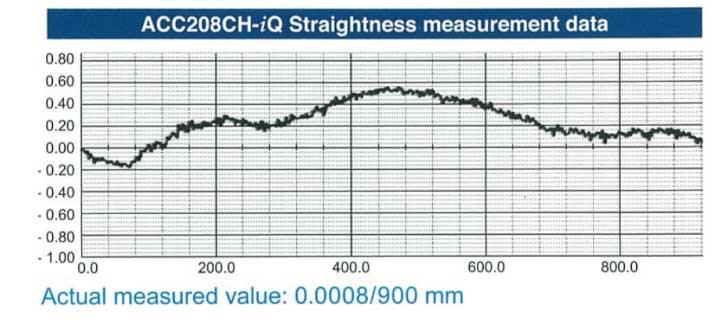

Highly accurate process

The accuracy of a double-column grinding machine depends on the crossrail. We have developed a crossrail mechanism that enables mechanical adjustment without NC correction.

Extremely high degrees of flatness canbe obtained along the entire width of the working surface.

Accuracy can be adjusted with the crossrail attached after installation.

Highly efficient process

- Pass width with extra space enables the processing of cross length of up to 1000 mm.

รองรับชิ้นงานกว้างถึง 1,000 มม.

- The 22 kw spindle motor offers the maximum horsepower in this class as option, with approximately 3 times the power of our conventional column-type machine.

- Dressing time has been shortened by combining upper dressing. (Option: dress correction function provided as standard) for rough dressing with table top dressing for finishing. Also the shift-plunge grinding cycle contributes to reducing the processing time.

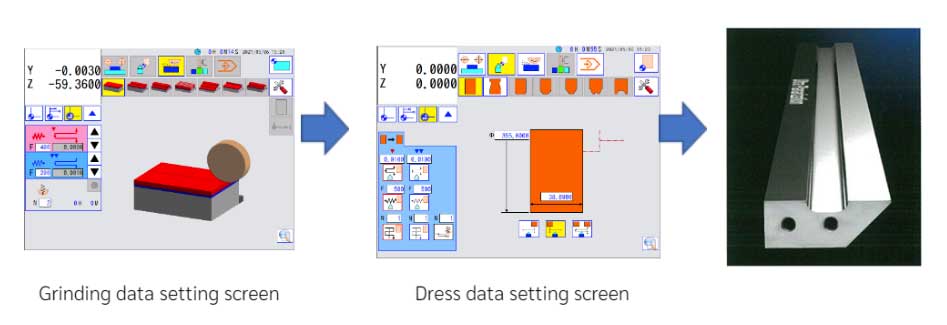

iQ software facilitates the processing of large workpieces with double-column grinding machine.

The innovative iQ software radically simplifies data input. Cycle time has been dramatically shortened.

iQ data is automatically generate by inputting the grinding wheel’s grain size.

Input the total machining allowance and precision machining allowance. Then, simply input the grinding wheel size to automatically create the optimum grinding wheel conditions based on our know-how and grinding process theory.

Data input can be completed using only two screens.

There is no text on the screen. The panel buttons cover the full range of surface grinding and complicated grinding operations.

Diversified iQ functions

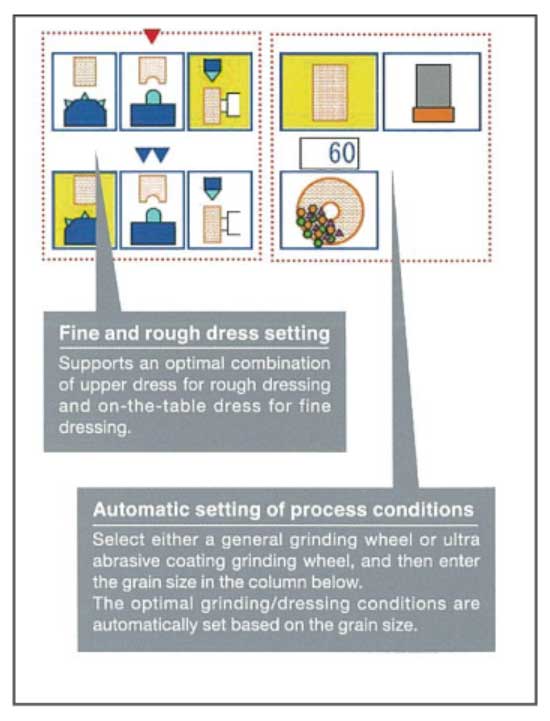

- Keys to shortening cycle time (Fine- and rough-dressing selection)

Optimum combination of upper dress for rough dressing and table top dress for finishing. An automatic diamond tracking device is provided with the upper dresser with dress cycle function (Optional).

By using shift plunge grinding, the cycle time can be effectively shortened.

- Automatic setting of process conditions

Grinding process used to rely on the user’s skill and intuition. To automate the processing, we developed a function for automatically setting the recommended process conditions base on grinding process theory and our know-how. The basic data on which this automatic setting is based on the grain size of the grinding wheel.

This software supports the use of both Alundum-type grinding wheels and ultra-abrasive-coating grinding wheels. Users can also input their own condition settings.

- iQ graphical display of actual grinding position

The position of which grinding is to be performed is displayed on the screen.

- iQ cycle type projection

The cycle end time is displayed. Thus saving setup time.

More information, please contact

OKAMOTO (THAI) CO., LTD.

Email : [email protected]

www.okamotothai.com