Elevate Your Precision Grinding with Okamoto's HPG500NC and Optional On-Machine Measuring Device “Quick Touch”

In the realm of precision form grinding, Okamoto stands as a beacon of innovation and excellence. The HPG500 Series introduces a paradigm shift with its revolutionary no-hydraulic system, delivering highly accurate positioning and stable grinding work that sets a new industry standard.

Okamoto HPG500 Series: Precision Elevated to New Heights

Embodying higher vertical and cross-positioning accuracy, the Okamoto Form Grinder ushers in a new era, eliminating hydraulic oil systems in favor of a more precise and environmentally friendly approach.

1. Unparalleled Precision

Achieve a minimum increment setting of 0.1μm for both vertical and crossfeed operations. Precision specifications are ensured through scraping alignment and the adoption of V-V sliding ways for longitudinal and crossfeed axes.

2. Unrivaled Rigidity

The grinding wheel main shaft rigidity is significantly higher than the previous model by 154%. In addition, the increased frame size increases cross-feed stability for optimal performance even in the most demanding tasks.

3. Environmental Stewardship

The non-hydraulic system not only eliminates thermal displacement but also reduces oil waste, significantly reducing CO2 emissions by 199.2kg.

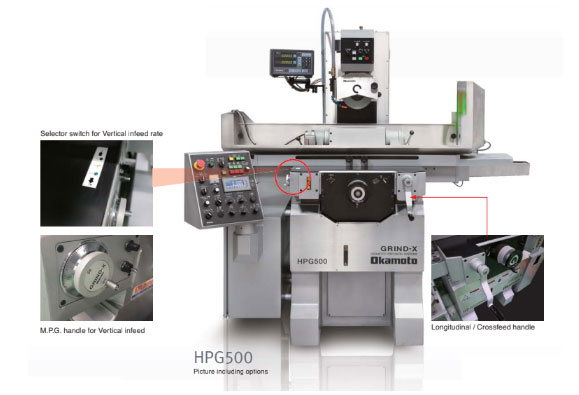

4. Effortless Operation

Featuring AC Servo motors for cross-feed, setup stroke by teaching, and convenient re-location of the M.P.G. handle and feed rate switch to the saddle side, operating the machine is intuitive and hassle-free. Vertical and Crossfeed scale feedback is standard specification. Wheel spindle motor 2.2kW and wheel spindle inverter also standard specification.

5. Form Grinding Automation with Conversational Software

Seamlessly integrating CNC control, Okamoto's Form Grinding Machine combines the ease of conventional machines with the precision of CNC, delivering precise wheel forms effortlessly.

6. HPG500NC High-Speed Stroke for Optimal Efficiency

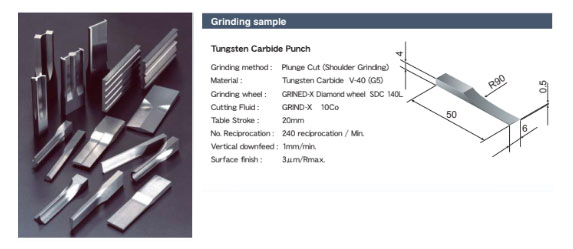

The HPG500NC High-Speed Stroke model is designed for high-speed, high-precision grinding, making it ideal for punch and small-formed workpieces. Its exceptional stopping accuracy and user-friendly operation system ensure top-notch performance.

Mold punch grinding with High speed table reciprocation: High-speed table reverse grinding is used to process die punches. Cycle time is greatly reduced by performing high-speed reverse grinding.

The Okamoto Advantage No-Hydraulic Force: Efficiency Elevated

1. Cost Savings for Oil: Bid farewell to regular hydraulic oil replacements and the associated disposal costs.

2. Carbon Emission Reduction: Witness a significant reduction of 656 Kg/KWH in carbon emissions associated with waste oil disposal.

3. Electricity Efficiency: Experience a 60% reduction in electricity consumption compared to traditional hydraulic table movement machines.

4. Eliminated Heat Source: Say goodbye to the challenges of controlling temperature with the elimination of hydraulic sources.

Optional On-Machine Measuring Device - “Quick Touch”

For those seeking the pinnacle of precision, the optional “Quick Touch” measuring device can be seamlessly integrated, ensuring every aspect of your grinding process meets the highest standards.

Elevate your precision grinding experience with Okamoto's HPG500 Series. Experience the future of form grinding where accuracy meets environmental consciousness. Contact us today and take your grinding capabilities to new heights!

More information, please contact

OKAMOTO (THAI) CO., LTD.

Email : [email protected]

www.okamotothai.com