High Efficient Shoulder Milling “DIJET” EXSAP/MSX

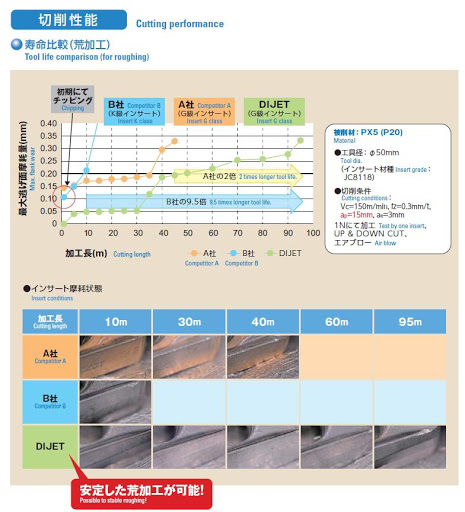

DIJET “SHOULDER EXTREME” EXSAP / MSX is shoulder milling cutter applicable to large ap machining is possible at maximum depth of cut at 15mm., usable for wide applications such as face milling, slotting and plunging.Due to high precision G class periphery grinding, applicable to not only roughing process but semi-finishing process. Therefore, DIJET “SHOULDER EXTREME” EXSAP / MSX can be widely applied such as general & mold steel and high hardened die steel up to 50HRC.

Efficient 1 Max. depth of cut (ap)=15mm is possible. EXSAP / MSX are usable for wide applications such as face milling, slotting and plunging.

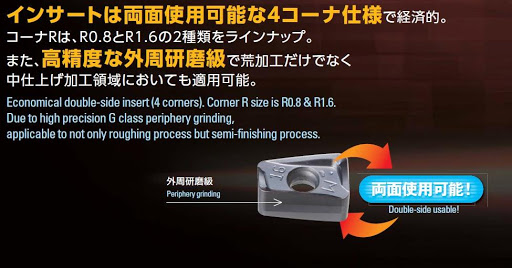

Efficient 2 Economical double-side insert (4 corners). Corner R size is R0.8 & R1.6. Due to high precision G class periphery grinding, applicable to not only roughing but semi-finishing process too.

Efficient 3 Our insert chipbreakers are designed with the state-of-the-art 3D technology to enhance the strength, hardness, and toughness of the edges. Our inserts, together with our super strong clamping system; they are fit even for the roughest of machining application.

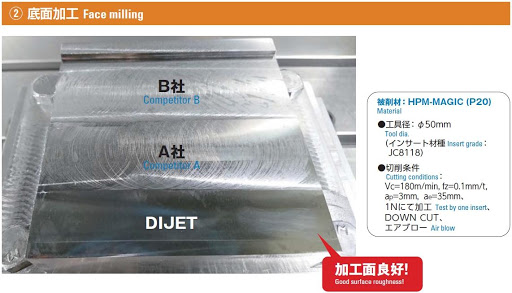

Efficient 4 2 insert grades are available: PVD coated grade “JC8050” achieved both fracture toughness and wear resistance. PVD coated grade “JC8118” provided high versatility and can be widely applied such as general & mold steel and high hardened die steel less than 50HRC.

Efficient 5 High precision G class periphery grinding, applicable to good surface roughness without hand grinding.

High Efficient Shoulder Milling “DIJET” EXSAP/MSX is really worked, see clip

More information, please contact:

Thai Worth Co., Ltd.

2/9 Serithai Rd., Kwaeng Kannayao , Khet Kannayao, Bangkok 10230

Tel. +66 2 736 4560 Fax +66 2 736 4694

www.thaiworth.com