YG-1 Launches ‘Dream Drill X’ with Advanced RCH-Coating Technology increase in tool life is 20% to 50% longer, Redefining Durability and Efficiency in High-Demand Drilling Applications

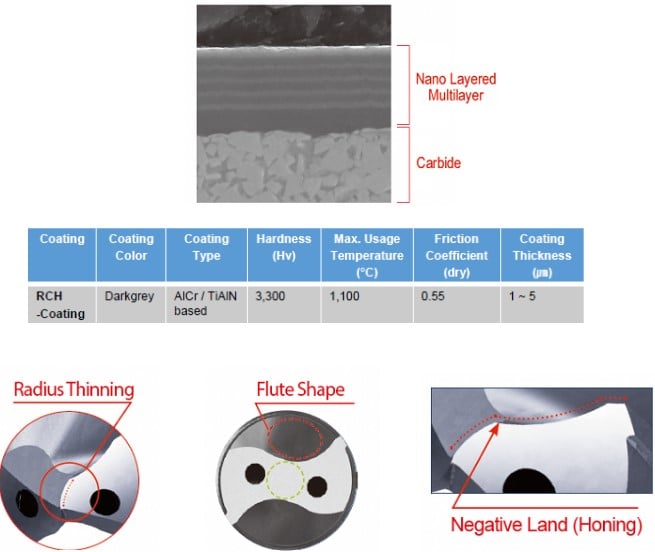

The newly introduced Solid Carbide Dream Drill X featuring the advanced RCH-Coating technology represents a significant leap forward in drilling tool performance. The coating combines the best attributes of TiAlN and AlCrN into a new ‘Nano Layered Multilayer’ coating generation, offering several advantages that set it apart from standard tools.

The newly introduced Solid Carbide Dream Drill X featuring the advanced RCH-Coating technology represents a significant leap forward in drilling tool performance. The coating combines the best attributes of TiAlN and AlCrN into a new ‘Nano Layered Multilayer’ coating generation, offering several advantages that set it apart from standard tools.

One of the standout features of the RCH-Coating is its exceptional wear resistance, which helps the tool remain sharp and effective over prolonged use. In addition, the coating provides high heat endurance, which is crucial for high-temperature applications with insufficient coolant supply. The coating also enhances chipping protection, reducing the likelihood of premature tool failure due to fractures or chipping. These features directly contribute to an increase in tool life, allowing the Dream Drill X to achieve a tool life is 20% to 50% longer compared to standard TiAlN-coated drills.

Product Feature

New Coating Technology “RCH-Coating”

- Improved Hardness and Toughness

- The RCH-Coating provides a higher hardness than TiAlNor AlCrN-coatings in general.

- High thermal stability and oxidation resistance

- At insufficient coolant conditions where higher temperatures occur, RCH-Coating allows with it’s very high temperature stability for great tool life results.

- The Nano-Layered Multilayerstructure prevents propagation of micro cracks

Universal point grinding

A universal point grinding for soft cutting action and reduced axial forces. It also addresses the need for trouble-free reconditioning.

Radius Thinning

The radius thinning providing very good self-centering even at low feed rates and unstable situations.

Tailored flute design

The tailored flute design enables excellent chip breaking and chip evacuation

Edge Preparation

A sophisticated edge preparation and the flat radius grind at the peripheral edges are maximizing tool life in various materials

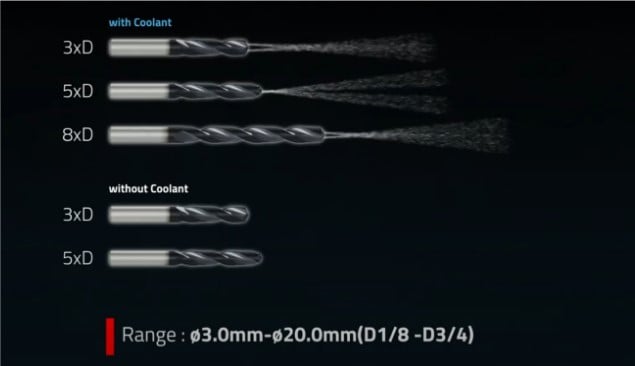

Possible applications for Dream Drill X are mainly Steel up to HRc50, certain stainless Steel and due to the high coating hardness especially Cast-Iron materials.

Customers seeking a drilling platform for daily needs can rely on the extensive portfolio and performance, eliminating the need for extensive testing and price comparisons.

- With attractive pricing and leading coating technology, we can regain customers.

- Current Customers will find Dream Drill X as a great opportunity to upgrade ensuring Customer satisfaction and loyalty in the future.

Brochure click below