TNC 640 high end control. Contouring Control for Machining Centers and Milling-Turning Machines from HEIDENHAIN

Contouring Control for Machining Centers and Milling-Turning Machines. For more than 35 years, TNC controls from HEIDENHAIN have been proving themselves in daily use on milling, drilling, and boring machines, as well as on machining centers. Below are examples of TNC 640 function.

Modern multitouch operation

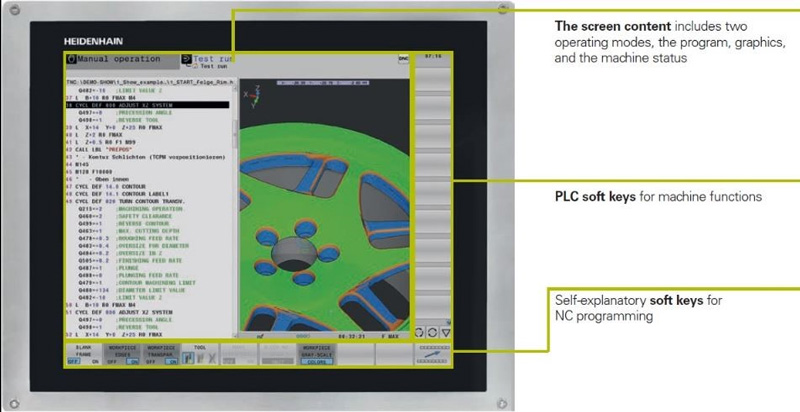

The large 19-inch screen shows a clear overview of all relevant information for programming, operating, and inspecting the machine tool and control, such as program blocks, comments, and error messages.

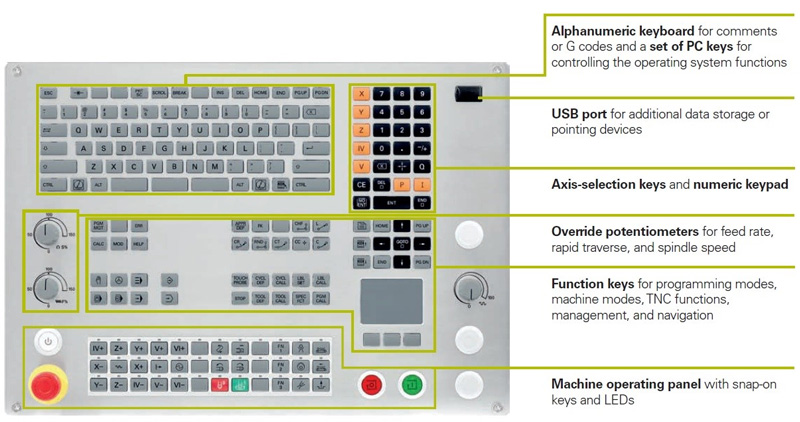

The operating panel

As with all TNCs from HEIDENHAIN, the operating panel is oriented to the programming process. The well-thoughtout arrangement of keys in a clear division into function groups

Multi-operation machining

The TNC 640 helps you to save time: on a milling-turning machine with TNC 640, you machine the complete workpiece in just one run—milling, turning, milling, in whatever sequence. After performing all operations on this one machine, you measure the finished workpiece with a HEIDENHAIN touch probe.

Dynamic Precision

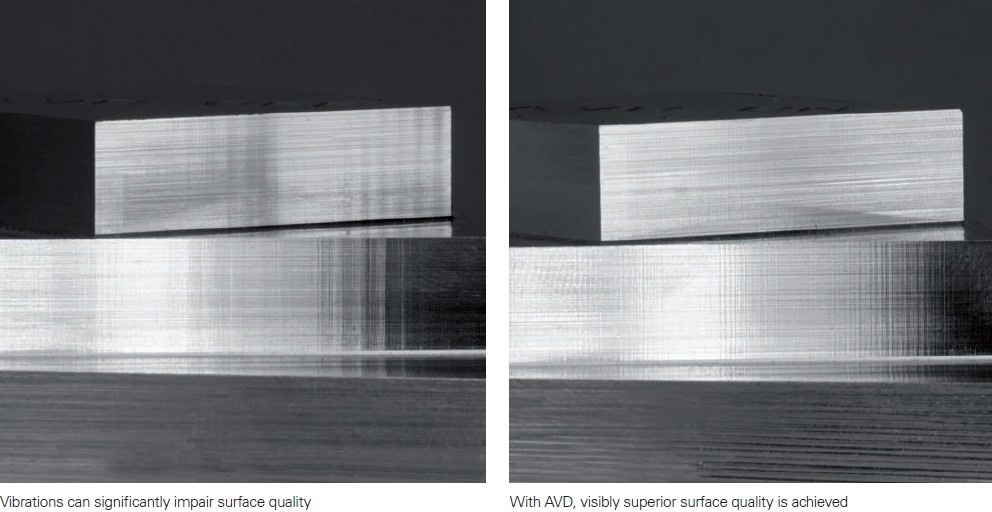

The hypernym Dynamic Precision stands for a number of HEIDENHAIN solutions for metal cutting that can dramatically improve the dynamic accuracy of a machine tool. Dynamic Precision includes the following functions:

- CTC: Compensation of acceleration-dependent position errors at the Tool Center Point (TCP)

- AVD: Active damping of drive train and machine setup vibrations

- PAC: Position-dependent adaptation of control parameters

- LAC: Load-dependent adaptation of control parameters and maximum axis acceleration

- MAC- Motion-dependent adaptation of control parameters

Youtube Clip (Dynamic Precision -- Machining Dynamically and with High Accuracy)

"HEIDENHAIN Dynamic Precision"

Quick and reliable machining with high contour accuracy

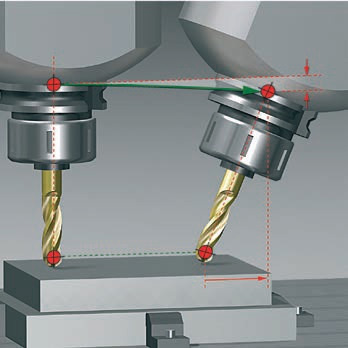

Regardless of what type of 5-axis programs, the TNC 640 performs all the compensating movements in the linear axes that result from movements in the tilting axes.

The TNC 640’s TCPM function (Tool Center Point Management)—an improvement upon the proven TNC function M128—provides optimal tool guidance and prevents contour gouging.

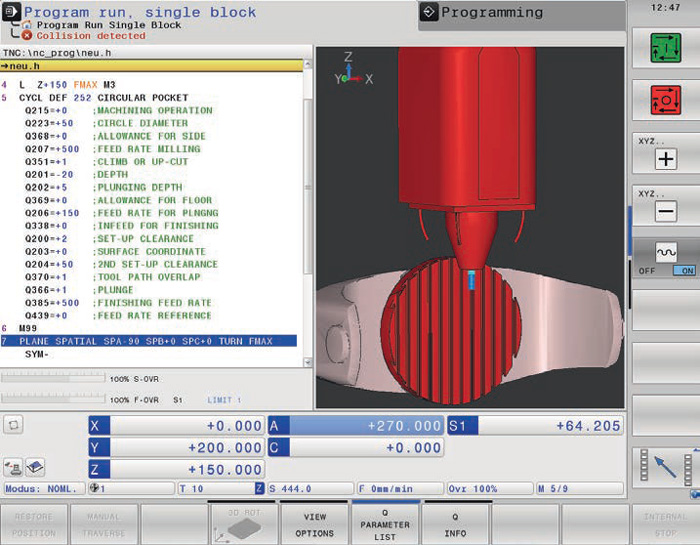

Dynamic Collision Monitoring option (DCM)

The control interrupts machining whenever a collision is imminent. This helps to prevent machine damage, which can result in costly downtimes.

Dynamic Efficiency

With Dynamic Efficiency you can manufacture more economically while increasing process reliability Dynamic Efficiency comprises three software functions:

1. Active Chatter Control (ACC): This option reduces chatter tendencies and permits greater infeeds

2. Adaptive Feed Control (AFC): The AFC option controls the feed rate depending on the machining situation

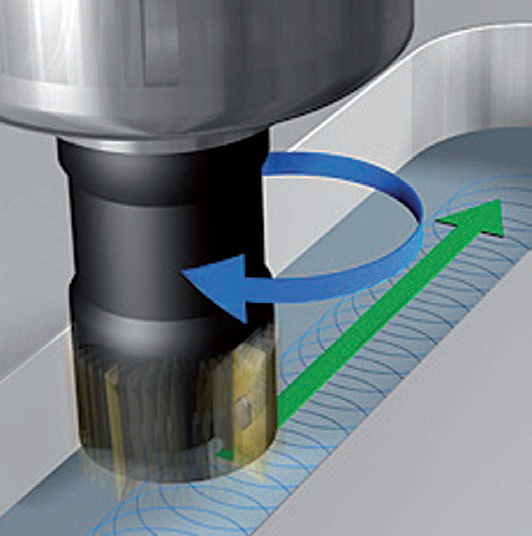

3. Trochoidal milling: A function for the roughing of slots and pockets that eases the load on the tool and the machine.

Youtube Clip (Dynamic Efficiency - the HEIDENHAIN solutions for efficient heavy machining)

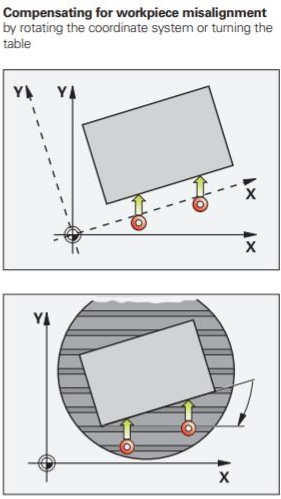

Minimize setup times

The TNC 640 features application-oriented, real-world setup functions. They support the user, help to reduce non-productive time, and make overnight, unattended production possible. Together with the touch probes, the TNC 640 offers numerous probing cycles for automatic alignment of the workpieces, presetting, and measurement of the workpiece and the tool.

This is just an example of all TNC 640 functions. For more information please follow the link https://www.heidenhain.de/de_EN/products/cnc-controls/tnc-640/

For more information, please contact

HEIDENHAIN (THAILAND) LTD.

+662 747 2146, +662 747 2147, +662 396 1840

[email protected]

www.heidenhain.co.th