Gühring Thailand: Driving Innovation in Cutting Tools at METALEX 2024

As the manufacturing landscape in Thailand continues to evolve, Gühring Thailand stands out as a leader in the cutting tool industry. In an exclusive interview, Mr. Ralf Alber, Managing Director of Gühring Thailand, shares insights into the company's market focus, innovative offerings, and strategies to address the challenges faced by the manufacturing industry.

Market Focus: Tailored for Key Industries

Gühring Thailand concentrates on three primary markets: Mold & Die, Automotive, and Aircraft. The company offers specialized tools for milling, tapping, drilling, and machining challenging materials such as aluminum and Inconel. This targeted approach ensures that Gühring’s product lines meet the diverse needs of these high-demand sectors.

What Sets Gühring Apart

Gühring’s competitive edge lies in its extensive product portfolio, which caters to nearly all machining applications. “We have the largest range of rotating tooling in the market,” said Mr. Alber. However, what truly differentiates the company is its One-Stop Service Center in Bangplee. This facility provides custom tools, regrinding services, and tool coating, supported by Gühring’s comprehensive tool management expertise.

METALEX 2024 Highlights: Low-Burr Milling in Aluminum

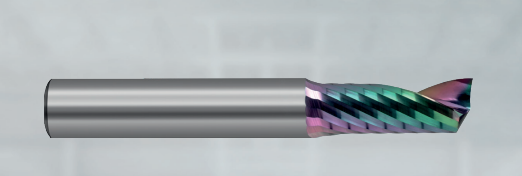

Gühring’s key highlight at METALEX 2024 is its solid carbide single-fluted cutter for burr-free aluminum profile machining, a cutting-edge solution that meets the growing demand for aluminum components across industries like e-mobility, aviation, and mechanical engineering.

Low-burr milling in aluminium

The tool features a large, polished flute for superior chip removal during aluminum and plastic machining, ensuring a safe and efficient process. With its very positive geometry, manufacturers can achieve low-burr cuts with minimal power consumption, making it ideal for dry and Minimum Quantity Lubrication (MQL) machining. Furthermore, the Carbo+ coating keeps cutting edges sharp, enhancing tool longevity and precision. The cutter is available in four designs, including an extra-long version with neck clearance to meet varied machining requirements.

Technological Advancements: Introducing SIRIUS

At METALEX 2024, Gühring is also unveiling its new range for hard materials with the SIRIUS coating technology, now available in Thailand. The SIRIUS coating extends tool life significantly, ensuring superior durability and cost-efficiency, which are critical for today’s manufacturers.

SIRIUS coating

Addressing Industry Needs

Gühring’s new tools are meticulously designed to cater to two critical needs in the manufacturing industry. The first is cost savings, achieved by reducing production expenses through enhanced efficiency and minimized downtime. The second is enhanced precision, with advanced designs and specialized coatings that deliver superior accuracy, meeting the evolving demands of modern manufacturing processes.

Key Industry Trends in Thailand

Several transformative trends are currently shaping the metalworking industry in Thailand and the region. One prominent trend is the increased price competition driven by Chinese manufacturers, who are dominating the medium-quality segment, putting pressure on local producers. Another is the growing adoption of aluminum and CFRP (Carbon Fiber Reinforced Polymer) applications, as these materials are increasingly favored across diverse industries. Lastly, the automotive market is undergoing significant disruption due to the influx of competitive Chinese automotive brands, which are reshaping the industry dynamics.

Overcoming Challenges in Manufacturing

The manufacturing industry in Thailand faces several challenges, including a shortage of skilled application engineers and a reliance on outdated, low-tech equipment. Mr. Alber emphasized the need for Thailand to embrace modern technology to remain competitive. “Most machines in factories today cannot support high-tech tools,” he noted.

Gühring aims to bridge this gap through education and advanced tools tailored for modern manufacturing needs. By providing cutting-edge solutions and knowledge-sharing initiatives, the company is committed to empowering Thailand’s manufacturing sector to reach new heights.

Looking Ahead

Gühring Thailand’s participation in METALEX 2024 underscores its commitment to innovation, quality, and customer-centric solutions. As the manufacturing industry continues to evolve, Gühring remains a trusted partner for manufacturers seeking to enhance productivity, precision, and competitiveness.

Although METALEX 2024 has concluded, the innovations showcased by Gühring, including their advanced tools and technologies, continue to set new benchmarks for the manufacturing industry. These solutions remain available to support manufacturers in overcoming challenges and driving efficiency, precision, and growth in an increasingly competitive market.