Sodick introduces V-LINE® technology for eco-friendly plastic injection in response to carbon reduction at Manufacturing Expo 2022 at BITEC

Sodick introduces V-LINE® technology for eco-friendly plastic injection to support the production of electric vehicle parts and biodegradable plastic products in response to carbon reduction at Manufacturing Expo 2022, June 22-25 at BITEC.

Mr. Hiromiki Goto, Director of Sodick (Thailand) Co., Ltd. , a Japanese manufacturer of Wire-cut/EDM machines with linear motor and high quality V-Line injection molding machines with a main production base in Thailand, spoke with M Report on the occasion of the event introducing technology and machinery for the manufacturing industry.

“Green & less carbon” is the key to today’s manufacturing

According to Mr. Hiromiki Goto, environmental measures to reduce carbon dioxide emissions are intensifying, creating demand for new products such as electric vehicles, biodegradable plastic products and packaging. These factors drive the industrial sector to adapt and seek technology to help it in terms of machinery, equipment, and manufacturing processes.

With this trend, Sodick machines have a great opportunity to expand in the categories of Wire-cut/EDM machines for the production of plastic molds and plastic injection molding machines. Sodick will highlight “V-LINE® technology, the exclusive patent of Sodick injection molding machines” at Manufacturing Expo 2022.

V-LINE® technology is a Sodick exclusive

All Sodick plastic injection molding machines employ V-LINE® plasticization and injection system technology, which separates the processes of plasticization and injection. This system led to the development of the zero backflow.

Sodick’s V-Line system has transformed traditional inline screw type molding machines by enabling accurate measurement of the injection amount, and control by numerical value became possible for the first time. At present, V-LINE®System is a registered trademark in Japan of Sodick.

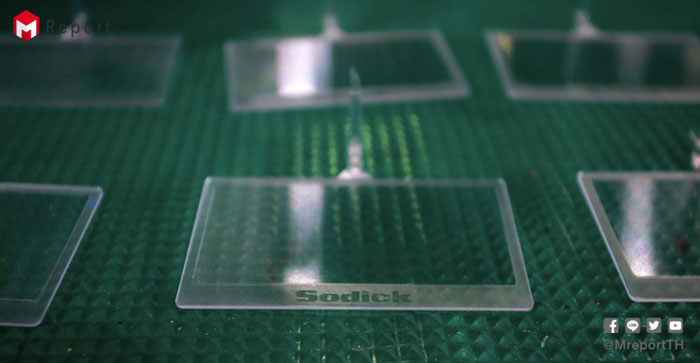

V-LINE® technology model inside the Sodick booth

The Sodick MS 100A plastic injection molding machine featured at this event is a small electric injection molding machine with high accuracy and stability for the production of small parts that require high resolution.

Sodick MS 100A plastic injection molding machine

The MS100A V-Line injection molding machine has distinct features that ensure precise reproducibility, is now powered by a servomotor. Measurements and positioning data for the injection locations are controlled in a closed loop to improve the precision of positioning, achieving remarkably stable repetitions of the plasticizing, measuring, and injection cycle. The line of injection units with plungers of 28 mm and 40 mm in diameters include models that emphasize speed and models that emphasize pressure, allowing you to choose the unit that best suits the molded product type.

With the servo motor drive and adoption of the mold clamping device by the original toggle link mechanism shortened the mold opening and closing cycle. The movable platen is supported by a linear guide to improve the stability of the mold orientation. The power design for these products significantly reduces power usage while contributing to quieter operation.

MS100A V-Line injection machine ensures precise reproducibility.

Mr. Hiromiki Goto added that, as a result of COVID, the demand for biodegradable plastics has decreased over the last two years, as has the demand for plastic reuse. However, things are changing. It is expected that the demand will increase in the future.

Sodick recently revealed the development of V-LINE® technology integrated with the INFILT-V system, which is an inert gas infiltration technology to use in such injection molding for biodegradable plastics. The inert gas will act as a plasticizer, which is an additive that reduces the viscosity of liquid plastic and enables both thin and thick plastic injection molding easily.

Current market conditions and trends

Mr. Hiromiki Goto revealed that machine sales are going well this year. Although it has not recovered as much as it did in 2019, it is still up 20-30% from the previous year. People are eager to purchase products as the COVID situation continues to improve. As a result, the demand for various products such as electronic components, automobiles, and others has increased.

He predicted that the situation would improve next year and commented on the Thai manufacturing industry’s investment trend, stating that business in Thailand has been doing well in recent months, particularly in the automotive sector.

Regarding the current chip shortage, Sodick has also been impacted by in terms of increased lead time. Previously, the machine could be delivered in less than three months; however, some products may now take up to 4-6 months. It is still unclear when the situation will improve because of numerous unknown factors such as the exchange rate, the Russian-Ukrainian war, and so on.