Renishaw: Transforming Manufacturing with AGILITY® CMM at METALEX 2024

Renishaw, a global leader in precision engineering and manufacturing technology, is set to make waves at METALEX 2024 with the launch of its AGILITY® CMM range. Steve Bell, ASEAN General Manager of Renishaw, shared insights into the trends, innovations, and applications that position AGILITY® CMM as a revolutionary tool for modern manufacturing.

Trends in ASEAN Metrology and Growth Opportunities

In the ASEAN region, manufacturing is shifting towards higher precision and faster data acquisition. “We see an increasing need for manufacturing companies to quickly gather actionable data on the increasingly high-accuracy parts they’re producing,” Bell explained.

Renishaw addresses these demands with its cutting-edge solutions, including:

-

Equator Automated Gauging Systems: Installed next to machine tools, these systems enable real-time measurement and adjustments, ensuring consistent part accuracy.

-

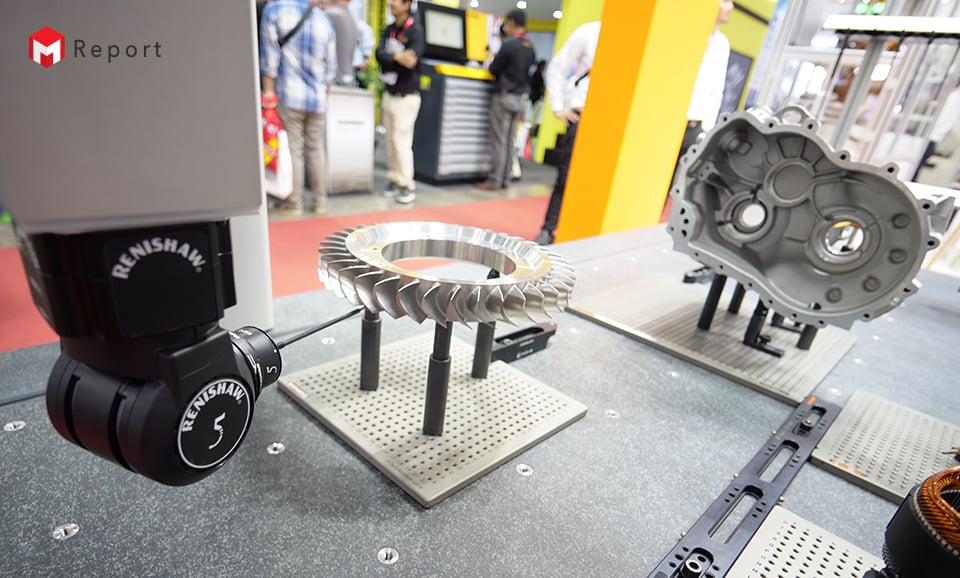

AGILITY® CMMs: Equipped with the REVO 5-axis head, these machines deliver fast feedback during final inspections, especially for complex components in aerospace and automotive industries.

Both solutions integrate seamlessly with Renishaw Central, a smart manufacturing data platform that collects and analyses process and metrology data. This technology empowers manufacturers with insights to identify and rectify errors before they occur, reducing downtime, enhancing productivity, and minimizing waste.

Renishaw Central

METALEX 2024: A Platform for AGILITY® CMM

At METALEX 2024, Renishaw aims to showcase how the AGILITY® CMM range can revolutionize manufacturing by combining speed, accuracy, and multi-sensor technology.

AGILITY® CMM

The AGILITY® CMM offers:

-

Integrated dimensional and surface roughness inspections.

-

Exceptional performance with 15% to 50% cycle time savings compared to traditional systems.

-

Enhanced durability through features like Renishaw Lightning Drive™ brushless linear motors and vibration-damping granite frames.

“Our objective is to demonstrate how AGILITY CMMs increase throughput and quality while reducing cycle times, making them indispensable for manufacturers aiming for precision and efficiency,” said Bell.

Key Advantages of AGILITY® CMM

The AGILITY® CMM offers advanced features that set it apart from traditional systems. Equipped with the REVO 5-axis multi-sensor system, it enables high-speed scanning, non-contact inspection, and surface finish analysis on a single platform. The machine combines granite for frame stability with anodized aluminum for dynamic elements, ensuring metrological accuracy across all applications.

REVO 5-axis multi-sensor system

Available in two variants, the S Range is built for shop-floor environments and maintains accuracy even without temperature control. Meanwhile, the L Range is designed for precision-focused industries like aerospace and automotive, delivering sub-micron accuracy even on the largest components.

Addressing Industry Challenges

The AGILITY® CMM range is tailored to meet the diverse demands of industries such as aerospace, automotive, medical, and consumer electronics. It addresses challenges like reducing inspection cycle times, achieving the highest accuracy for critical components, and ensuring reliability across both standalone and automated production environments.

By combining innovation with real-world manufacturing needs, Renishaw's AGILITY® CMM is reshaping the standards for precision and efficiency in industrial metrology.

Future Innovations

Renishaw’s commitment to innovation remains unwavering. “We will continue to explore additional sensor technologies and enhance throughput while maintaining unmatched accuracy,” Bell affirmed.

Renishaw’s AGILITY® CMM represents a leap forward in metrology, combining speed, accuracy, and intelligent data integration to meet the demands of modern manufacturing for excellence in efficiency and quality.

#Renishaw #AGILITYCMM #METALEX2024 #CMM #Metrology #Mreport #IndustryNews