Secret unveiled -- Japan creates system integrator

Japan is an aging society, lacking labour. It is therefore unavoidable for the country to utilize robots and automation systems in its production lines. Large operations highly succeed in utilizing robots whereas small and medium enterprises lack competent personnel to control robots, holding back their decision to make use of the automatic devices. Another critical factor is the fact that there are very few specialists in system integration, and most of them often work for large companies.

What is a system integrator?

The practical utilization of a robot requires an individual who studies the application procedure, selects core devices, designs and produces accessories, writes programs and arranges working procedure of a robot. This individual is called “System Integrator” or SI.

Generally, robot manufacturers define their roles as only device vendors and technical information providers. Other responsibilities will become those of a system integrator who will fulfill the work. The development of a system integrator therefore plays a vital role in encouraging the robot utilization, motivating SMEs’ robot supply and emerging extensive application of robots.

SMEs consider robots a distant issue.

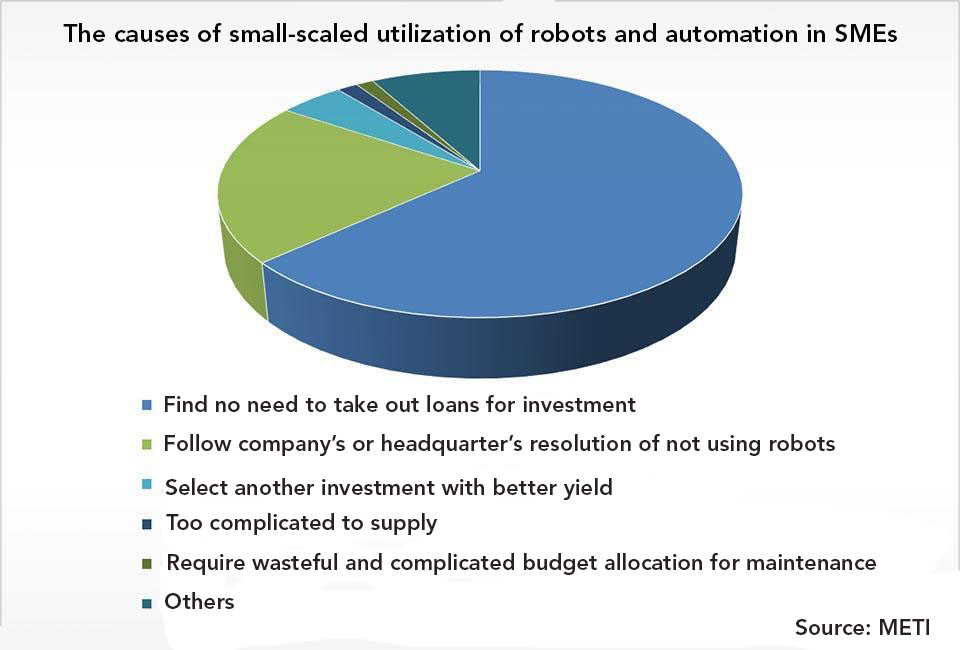

The Small and Medium Enterprise Agency conducted a survey in Japan in 2016 to reveal the causes of a small scale of SMEs’ utilization of robots and automation system. Apart from lack of specialists, there are also other combined causes. Over 60% explained, “It is not necessary to take out loans for a boost to investment.” They think that such an investment requires a large amount of money as well as dramatic improvement. Even many of them consider that robots are too distant issues and unnecessary to be applied in their business.

Opposite requirements between “Robot Manufacturers” and “SMEs”

Apart from the aforementioned obstacles resulting in system integrator’s essential role, robot manufacturers and SMEs have requirements that are as different as chalk and cheese, accelerating the importance of a system integrator.

The former wish to manufacture high-quality robots that can perform more and more complicated tasks while the latter demand the ones that require small investment and are easily supplied. The automated machines are then utilized for the jobs that are risky like moving things, done in high or low temperature workplace, and in need of special accuracy.

System Integrator’s responsibilities

For those reasons, a system integrator’s responsibilities vary widely, from analyzing manufacturing process of clients’ businesses, designing systems for robot application, performing robots’ basic set-up, and so on, to assembling and installing robots for clients, guiding how to set up and tune the devices so that they can be smoothly utilized in factories. The most significant role of a system integrator, however, is to design a concept for the most suitable solution. It is therefore predictable that the market’s requirements for a system integrator will be ascending more from now on. That is to say, this demand exists in almost all industries.

Besides, there are other potentials to enable system integrator business to grow significantly by pursuing the knowledge of robot and its production line. Nowadays there exist a couple ideas of enabling a robot to be applied simply and diversely, such as

- Robot’s arms with changeable hands as required by Denso’s clients

- The concept of a 3D printer to print a robot’s hands that match Musashi’s job

- The concept of simple IoT that uses a sensor system integrated with stickers, a robot controlling monitor that is simply used, or a data storage created in the form of video for instruction or troubleshooting with an officer who can provide remote assistance

Immense cooperation arises

To produce adequate numbers of system integrators who specialize in various applications covering market’s requirements is marked as great cooperation financed by Japanese government sector in collaboration with the private sector. This includes all robot companies, spare part manufacturers – the main users of robots, and universities – the indispensable partners.

Today, a training course on industrial robot supply is offered by Nagoya University or Nagoya Institute of Technology, a leading educational institution of science and technology in Nagoya and one of the best universities of engineering in Japan, which is located in Nagoya, the center of Japan’s automobile manufacture. The collaboration outcomes will encourage system integrators who need to have knowledge, specific information and techniques to acquire knowledge from a team of experts sent by robots companies as lecturers and trainers, as well as to visit their showrooms. The course to produce system integrators at Nagoya University opens only for ones who are responsible for industrial machinery installation, or ones who work in a factory with similar tasks. Background knowledge of robots is not required.

Then a system integrator’s manual has been launched. It is a collection of basic data for ones who need the supply of robots. The terminologies, chosen by outsiders not specialists, are easy to understand. Explanations of extensive procedures are provided, starting from decision making for robot utilization, process of each operation, and introduction to robots and other related machines to the formulation of security measures. Also, an association has been founded to support the collaboration and the matching of SMEs’ and system integrators’ requirements in order to enhance the optimization of robot supply. In addition, the web-based directory has been prepared to combine robot application guidelines and system integrator’s data.

Besides, Nagoya University has innovated the supportive network of industrial robot utilization as a platform to collect the name lists of SMEs, system integrators, robot manufacturers and other related organizations. The purpose is to support information exchange and personnel training.

Achievement of the project

Business of various types achieves the utilization of robots:

- Shiokawa, food business, where Yasunaka Denki helped with the installation of robots for packing mushrooms into trays without damaging the products.

- Kaneko Optical, where Yamaha Fine Technologies installed Grinding Robot for polishing optic lens in order to unburden the workmen.

A beverage factory with the utilization of multi-branded robots

Nagoya University presented a sample of a beverage factory which does not limit its robot application to only one brand. On the contrary, suitable robots are selected in accordance with the operation of each process. It is therefore a system integrator’s responsibility to match the user’s requirements with suitable robots and perform the installation to ensure uninterrupted joint operation.

- The production of bottles operated by Fanuc’s robots

- The quality examination of the produced bottles performed by Denso Wave’s robots

- The packaging of bottles done by Mitsubishi Electric’s robots

- The quality examination of package performed by Yaskawa’s robots

- The assembly of robot containers operated by Kawasaki’s robots

The robots from these five brands are connected through IoT device to monitor and control the operation an increase the operational efficiency of each process. The workpiece is transported and controlled by VR Technology, playing the role of a system integrator in designing and installing all these machines.

The factory’s model is currently exhibited at SI Center, Gifu, as a sample to demonstrate the operation. There are also 209 system integrators examined and certified by Japan Robot Association (JARA).