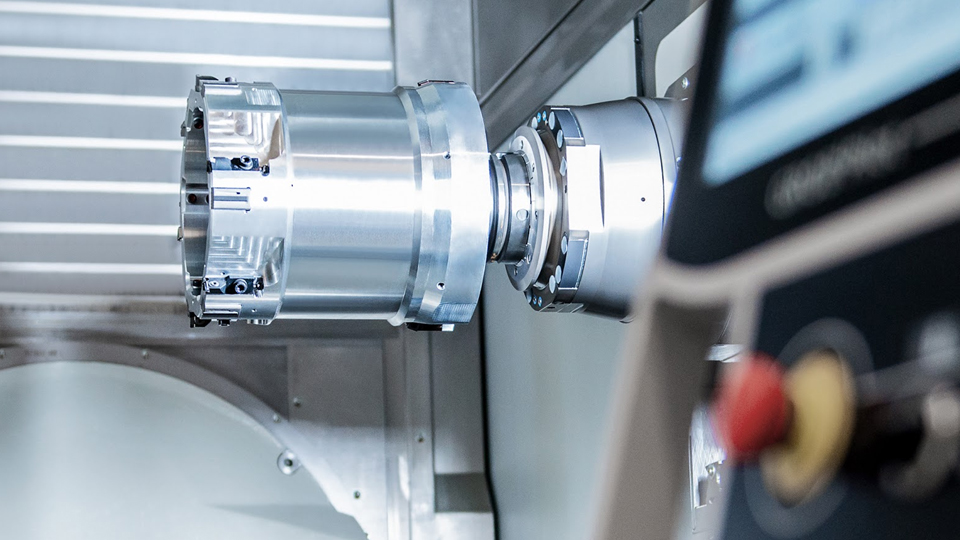

New. Extreme. Powerful. RT 100 XF Ratio drill. From Gühring in EMO Hannover 2019

120 years of manufacturing expertise, innovation and synergy:

These are the pillars of our success that have allowed Gühring, once a pioneer of drilling solutions, to develop into an industry-leading full-service provider. This was made possible by our own R&D departments in geometry, production and coating, the production of proprietary carbide, as well as grinding and coating systems. These elements find their way into the performance of our products, enabling us to continually set new standards for the industry.

This leading expertise serves as the basis for the new RT 100 XF Ratio drill. Exceptional performance and a qualitative advantage. With unrivalled power and guaranteed outstanding machining results for your processes.

New carbide and nanoFire coating

Extremely hard, absolutely unbreakable: the carbide, which has been specially developed for the RT 100 XF, performs a balancing act between hardness and toughness through the unique combination of tungsten carbide and cobalt. The special structure of this composite cutting material has a re-sharpening effect. Major breakages that normally accelerate tool wear no longer occur.

In addition to titanium and nitrogen, the tried-and-tested nanoFire coating system also contains aluminium and is characterised by a high level of hardness and good thermochemical resistance. Finishing in particular has been optimised through the holistic approach, meaning that there is an optimum connection between the newly developed carbide and the tried-and-tested nanoFire coating. This specially designed pre-treatment and post-treatment smooths the coating and therefore makes it significantly more robust.

RF 100 Speed P and M

The 5 and 7 Speed add to the established RF 100 Speed range with the P and M material specialists. They are suitable for GTC machining at an ae of up to 15%. Thanks to the high spiral angle of 48° with unequal cutting edge distribution for soft, quiet cutting and large flutes, the FT 100 Speed P and the RF 100 Speed M ensure a low load on the machine and power consumption. The lower number of teeth provide maximum chip space for good chip evacuation. Different versions of the milling tools are available. The long version has chip breakers in order to break chips into short pieces and therefore ensures smooth chip evacuation. Large face chip spaces and the improved web thinning enables reliable plunging. The optimised corner protection chamfer and face correction protect the cutting edge corner, as the most delicate part of the tool, from two sides, meaning that the cutting edge is also able to withstand heavy shear loads. Through this combination, the tool life is significantly longer.