New Technology Reduces Vibration in Machine Tools

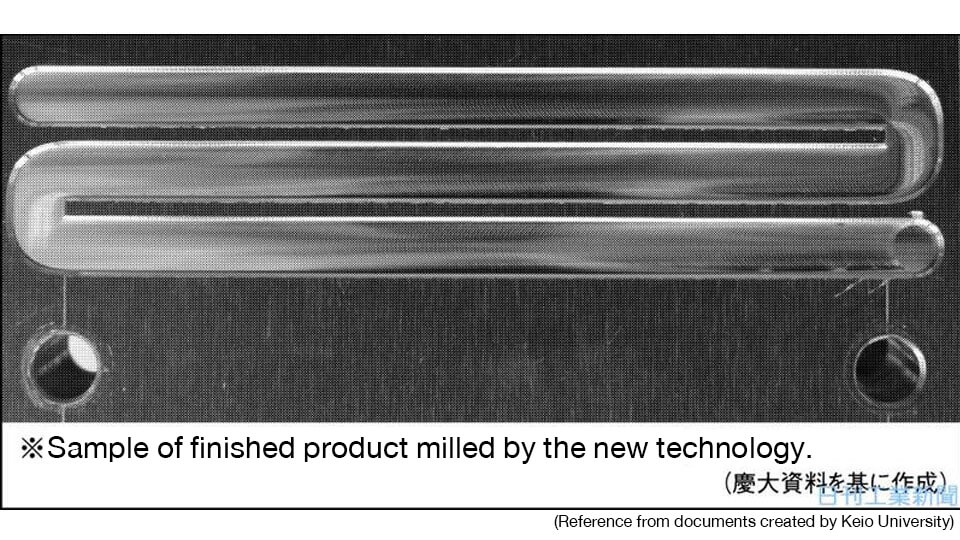

Associate Professor Yasuhiro Kakinuma at Keio University and Associate Professor Sencer Burak at Oregon State University along with the team have jointly developed a new technology to control machine tools to reduce the impact of vibration on the workpiece automatically and are currently proposing this technology to machine tools manufacturers.

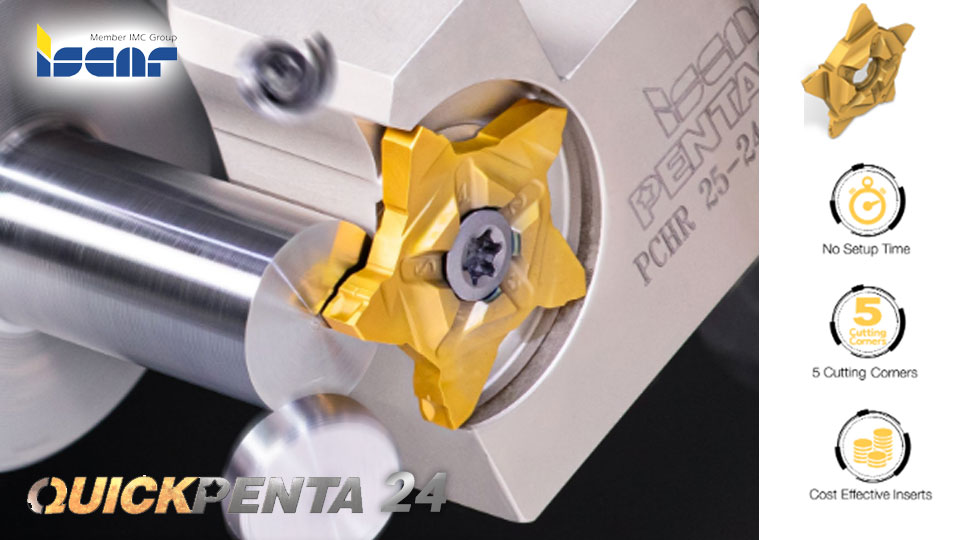

Up until now, machine tools work by using the movement of the tools and the workpiece, resulting in vibrations in the machine and thus possibly rough marks on the workpiece surface. To prevent such problem, the research team therefore designed a new approach of cutting workpieces based on the vision that if the cause of the problem or the vibration could be prevented, then the surface damage could be avoided.

The new approach of cutting workpieces does not have any changes in the way of holding the piece and the cutting angle. However, it involves in the spindle speed of the tool and the worktable, in which these two components can automatically adjust its speed to be in line with the machine operations so that there is minimal vibration.

In the past, the control of internal vibration is done by using filters. However, these filters can control only the vibrations as set and in reality, the vibrations can occur beyond this. For this reason, the research team chose to use three types of filters in order to be able to handle a variety of vibrations in all three axes and can successfully reduce the expected movement from 0.10 micrometers to only 0.05 micrometers.

This new technology makes the vibration reduction in small machines or machines with complex structures successful without the need to increase the strength of the structures and axis in the machine at all.