Epson launches “high-tech robot” primed for Thailand’s new gameplan towards high-potential industries

Epson’s launch of the “T-B series” SCARA robot, the highlight of METALEX March 2022, signals being primed for Thailand’s new gameplan towards high-potential industries.

Mr. Yunyong Muneemongkoltorn, Managing Director of Epson (Thailand) Co., Ltd. openly gave us an interview as a key player in the Thai robot industry that is playing an important role in the country's development towards a high-potential industrial strategy.

How is “Epson” and “robot arms” related?

When mentioning Epson, I believe that many people would think of printers most of the time. In fact, Epson is one of the leading manufacturers of high-tech industrial robots. Epson has been in the industrial robotics industry for over 39 years and is recognized as a highly accurate and stable robot, making Epson the world's No. 1 SCARA robot leader since 2011.

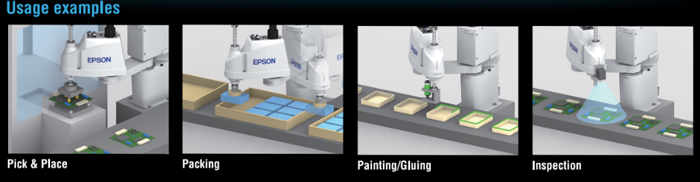

Initially, Epson produced the SCARA robot for the assembly of Seiko Epson watches, where the precision of the watchmaking process was extremely demanding. With our long experience in high-precision, compact, energy-efficient robotics technology, Epson robots have evolved into many models of slim, light-weight industrial robots. Epson robots are widely used, especially in the electronic parts production line, which is our main customer group. They are also used in the production of automotive parts, medical equipment and other industries that require precision, which Epson robots are accurate up to 10 microns (μm).

In addition to its outstanding vision technology, sensing technology, and vibration control technology, the Epson robot has taken its reliability to another level in terms of speed, accuracy and efficiency in process automation. The highly automated production lines in factories around the world have Epson robot workers involved as part of their achievements.

In the ultimate automated production line, having low long-term cost and overhead, or low TCO, while being highly reliable are two key factors inherent in Epson robots. It delivers high productivity, high quality, and easy operation through integrated software.

Epson launches high-tech “T-B series” SCARA robot, the highlight at METALEX March 2022

At METALEX March 2022, Epson brought its full lineup of robotics and automation solutions to showcase. The highlight was the new “T-B series” SCARA robot, which is a compact, easy-to-use, 4-axis SCARA robot that comes with a built-in controller. With its economical price, it can be bought on a limited budget. It requires low power consumption and low operating costs, making it suitable for both novice and advanced robot users.

Epson T-3B SCARA Robot

The Epson T-B series SCARA robot equipped with a built-in controller reduces installation space and does not require complicated wiring, which simplifies the installation of the robot. The T-B series offers up to 7% more stable speed and positioning performance compared to the original ones.

Its batteryless motor retains the position of the starting point in the memory unit, eliminating battery replacement. This reduces operating costs and reduces the downtime of the production line, so keeping overall robot operating costs down. Therefore, the T-B series is a cost-effective and worthwhile robot. It is suitable for manual automation and also replaces the installation of automated lines that use a large number of single-axis or multi-axis robots that are difficult to install and maintain.

Epson’s SCARA T-B series robot is the first choice to consider for pick-and-place type of work. It makes manual automation simple and truly economical. Installation and maintenance are easy. It provides high work efficiency, which means it saves money every time you use it.

Currently, the T-B series comes in two models: the T-3B supporting 3 kg for smaller parts and the T-6B supporting 6 kg for heavier parts.

Epson’s premier SCARA robot is ready to stand by Thai entrepreneurs’ side towards high-potential industries.

Mr. Yunyong revealed that the robot arm market in Thailand and around the world has been growing well because the robot arm can help increase work efficiency. Its high accuracy makes it possible to control quality. It can also be used to replace workers whose wages are continually rising.

In particular, during the past two years of the COVID-19 outbreak, there were clusters of those affected in many factories with a large number of employees, which caused the manufacturing to be interrupted. Therefore, robot arms are brought in use to minimize risks, reduce labor, but still maintain the working efficiency. These factors have made the robot arm market grow strongly over the past year. When compared to other countries in the ASEAN region, most of the multinational companies investing in Thailand are factories that use robots and automation in the production line, which makes the robot arms market in Thailand grow more than other countries in the region.

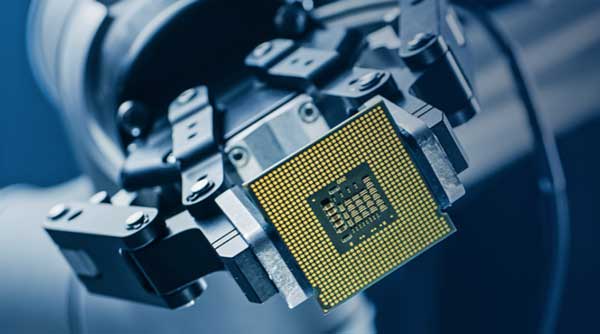

In addition, many policies of the Thai government to promote investment, give tax incentives and support human resource development have greatly contributed to the growth of the Thai robot industry. The next phase of prospect is to push on new industries with high potential or new S-Curve ones, in which the government is working on. In some sectors, there has been significant progress, such as electric cars. Another industry that is believed there will be more investing capital coming in is electronics and semiconductors. This is because it is a product that is in high demand due to the growth of smart electronic devices that have become part of many products such as automobiles, smartphones, machines and many other devices.

These trends will allow the industrial robot market to grow steadily, especially high-precision robots. This good business opportunity certainly allows customers to have more options in choosing the technology for the production line and to position their business with superior competitiveness. Epson Robot is confident that we are a good choice for automated production lines of all levels. In addition to the strength of the Epson robot itself, the consulting and after-sales services are also important things that Epson has been doing. We have Epson Robotics Lab, an agency that makes a simulation of automation solutions designed for clients to see before making an investment decision. Epson also collaborates with a system integrator (SI) to complete the design of automated production systems with low downtime or low TCO.

However, robots can work in place of humans, but not in all aspects. Robot investment and human resource development should go hand in hand for better results. Robots should be used to perform repetitive or dangerous tasks while humans do the work that require higher skills.

For entrepreneurs who are not sure whether to switch production to automation or not and how to do it, it is advised to identify the problems first. Each factory has different problems and there is no fixed formula for how to solve them. Once the problems are identified, then it comes to the design of automation and the selection of robots that are better suited to their factories. Since investing in robots incurs costs and is a long-term commitment, the investment decision process is the most important thing.

For those who are interested, you can view a wide range of Epson robot products at the Epson Virtual Solution Center.

See Epson Robotics Innovation, click!!