Integrate to Innovate: Insights from TIMTOS Keynote x Forum 2025 on the Future of Manufacturing

Integration for Innovation: The New Direction of Manufacturing in the AI & Robotics Era

In an era of rapid technological change, the manufacturing industry is undergoing a major transformation. Under the theme "Integrate to Innovate," TIMTOS 2025 has become a global platform shaping the future of machine tool industries, particularly in AI & Robotics, Smart Manufacturing, and Green Sustainability. TIMTOS Keynote x Forum 2025 presents perspectives from global industry leaders, offering new approaches to driving the manufacturing sector into the future.

AI & Robotics: The Future of Smart Factories

One of the key highlights of TIMTOS 2025 is the role of Artificial Intelligence (AI) and Robotics in revolutionizing the manufacturing industry.

Akihiro Teramachi, Chairman and CEO of THK, stated, "Integrating AI into automation systems is the key to enhancing production efficiency, reducing costs, and increasing flexibility in manufacturing lines."

Notable AI & Robotics Technologies Unveiled at TIMTOS 2025:

- TM AI+ Trainer by Techman Robot – An intelligent robot that learns and adapts through Machine Learning.

- LSR-05 by THK – A prototype electric vehicle introduced in 2023, combining THK’s expertise in Linear Motion with AI technology to reduce wear and improve the precision of its drive system.

- AI-driven Production Management System by Siemens – Utilizing Digital Twin technology for real-time analysis and production optimization.

By 2025, Smart Factories are shifting from concept to reality. The integration of AI with robotics significantly reduces machine downtime, enhances product quality, and minimizes waste (Waste Reduction).

Smart Manufacturing: When Production Becomes Smarter and More Flexible

The transformation of the manufacturing industry goes beyond AI & Robotics, encompassing Industrial Internet of Things (IIoT) and Automation to minimize waste and maximize efficiency.

Paul Chen, VP of Business Development at FFG MAG Automotive LLC, remarked, "Powertrain Machining is a key solution for intelligent and high-performance powertrain systems, emphasizing Turn-Key Integration for faster cycle times, unmatched precision, cost-effective production, and flexible automated production lines."

Hitachi Yoshida, Chairman and CEO of Tokyo Seimitsu, stated, "Advanced Digitalization and Carbon Neutrality are the key elements of future manufacturing."

Key Trends Discussed at TIMTOS 2025:

- Digital Twin – Creating digital replicas of manufacturing processes to enhance efficiency and reduce errors.

- Flexible Production – Production lines that can adapt to real-time market demands.

- TM AI Robot – AI-powered robotics that enhance human-robot collaboration.

- AI-Driven Quality Control – AI-powered inspection systems that improve accuracy and minimize waste.

- Precision Measurement in Production Environments – Utilizing Machine Learning and AI-Powered Metrology for 100% Inspection, integrating fully automated quality control processes to achieve Zero Defect production lines.

The integration of AI, IIoT, and Automation not only increases factory efficiency but also enables faster responses to customer demands.

The integration of AI, IIoT, and Automation not only increases factory efficiency but also enables faster responses to customer demands.

Green Sustainability: When Manufacturing Must Be Environmentally Friendly

Green Manufacturing is becoming the new industry standard, with leading companies accelerating the development of technologies that reduce energy consumption and carbon footprints.

Christine Herbst-Kubitz, General Manager of Siemens Taiwan Digital Industries, stated, "Sustainability is no longer an option—it is a standard driven by both customers and regulations."

Maurice Chang, Global Sales & Marketing Senior Director of Hiwin Technologies Corporation, added, "AI and Sustainability are driving the growth of the Smart Manufacturing market, which is projected to reach USD 620 billion by 2026. Hiwin focuses on solutions that reduce waste and pollution. Hiwin Linear is developing humanoid robots, while Hiwin Mikrosystem concentrates on solutions for the semiconductor industry."

Key Green Sustainability Trends from TIMTOS 2025:

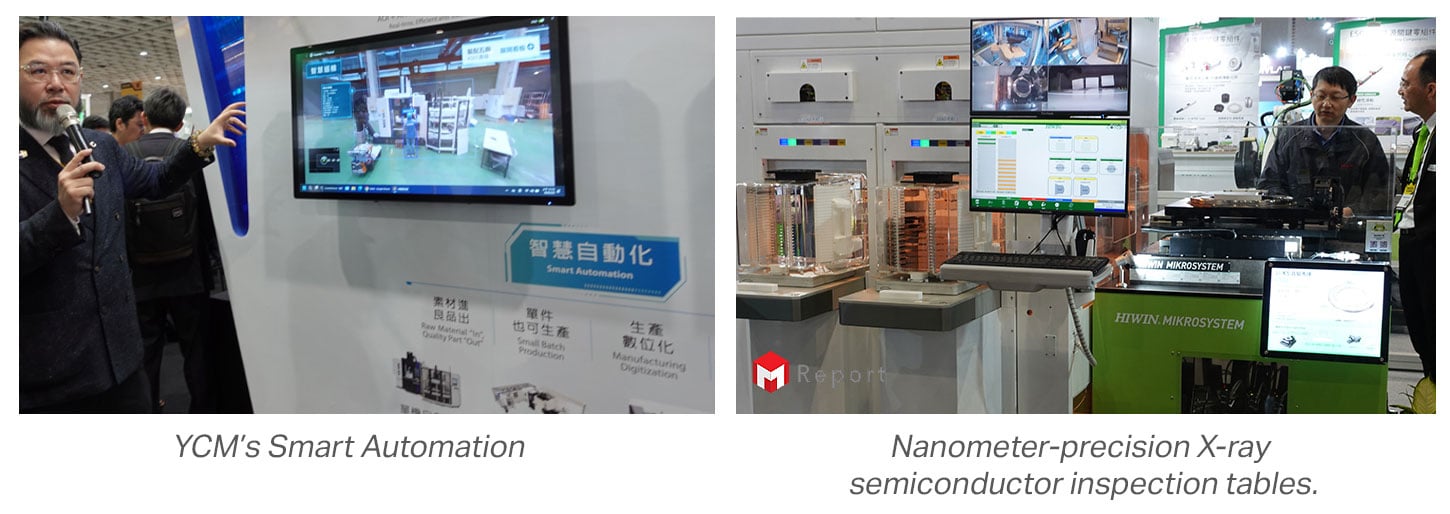

- YCM’s "Green x Smart" Concept – Utilizing Generative AI to enhance customer experience and competitiveness, integrating real-time quality inspection within machines to reduce waste and optimize automation.

- Keyarrow’s "Purifying Forest" – A Chip Conveying and Filtering System designed to minimize waste and promote Circular Economy principles.

- Hiwin Mikrosystem’s Motion Control Systems – New Direct Drive motors for the semiconductor industry that reduce energy consumption and enhance efficiency, enabling component sorting at speeds of 0.06 seconds per cycle and nanometer-precision X-ray semiconductor inspection tables.

Conclusion: Integrate to Innovate – The Path Forward for the Modern Manufacturing Industry

TIMTOS 2025 has demonstrated that success in the machine tool industry is no longer just about having the best technology—it is about effectively integrating various technologies. Whether in AI & Robotics, Smart Manufacturing, or Green Sustainability, companies must adapt and innovate to stay competitive.

For Thailand's manufacturing industry, adopting these concepts involves:

- Investing in AI and Automation to enhance efficiency and reduce production costs.

- Utilizing Smart Manufacturing strategies to analyze data and optimize production processes.

- Advancing towards Green Manufacturing to improve competitiveness and comply with global environmental standards.

The integration of these technologies will be the key to keeping Thai manufacturers competitive on a global scale. This is what "Integrate to Innovate" truly means.

Are you ready to step into the future of manufacturing?

#TIMTOS2025 #IntegrateToInnovate #MachineToolShow #SmartManufacturing #AI #Automation #MReport #IndustryNews