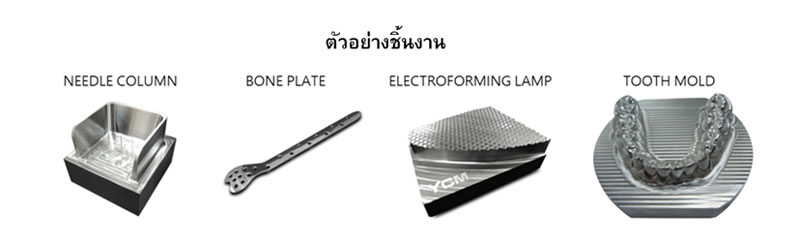

YCM Micron Workpiece Made in Taiwan

At present, moldmaking and workpieces with micron resolution are in greater demand in many industries such as molds in the IT industry, LED light molds, high definition plastic molds, canned food packaging molds, progressive die molds, and medical parts. It is a golden opportunity for those who are able to manufacture these pieces. The ability to produce work in micron level should be the next potential target that the Thai manufacturing industry must reach. This article will explore the possibilities and bring you to the production of micron level workpiece from NSV 106AMS machine, which is a special model that the leading brand YCM Made in Taiwan designs and manufactures specifically for milling a fine mold.

What is Micron?

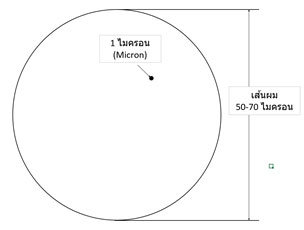

Micron or micrometer is a unit of length which is equal to 1×10−6 meter or 0.001 millimeter. Compared with a human hair that is about 50-70 microns, a micron is very small.

The picture shows a comparison of micron size and human hair.

Production of Micron Workpiece

Micron resolution production is still a new thing for Thai entrepreneurs, especially the understanding about the environment specifications, machine features appropriate to the needs, cutting tools needed, and how to select the machine tool holders and workpiece jigs. Many people think that just buying a high resolution machine and one can do fine work.

Stable Space and Temperature Controlled Room

Since the machine with high resolution often has a lot of weight, for stability while milling the workpiece, the machine should be installed in the area that has good load-bearing capacity and away from any vibration from the surrounding. Since the machine is built with steel and steel elongates and contracts due to temperature changes, that is, every 1 degree change in temperature, the steel will contract more than 10 microns per 1 meter in length, therefore, the change in room temperature will affect the details of workpiece milling. Air-conditioned rooms and air conditioners are generally designed to provide comfort to humans, in which normally the cool air released may vary from the return air up to 4 degrees, which means it may cause the machine spindle to shrink up to 30 microns, making controlling the resolution difficult. The room that will be able to do micron-level milling must have a difference in temperature around the machine +/- 0.5 degrees only.

The Machine

When it comes to machines for micron fine finishing, entrepreneurs probably first think of machines from Switzerland, Germany and Japan, which is known for high technology and efficiency. In fact, Taiwan is the 4th largest exporter of machines in the world and can manufacture high-precision machines, especially the leading Taiwanese manufacturer like YCM, who has over 60 years of machine manufacturing experience. YCM not only can make high resolution machines comparable to many manufacturers in Europe and Japan, but also export them to all over the world, including Europe, the United States, and Japan.

Mr. Rick Chen, the president of Yeong Chin Machinery Industries Co., Ltd., a leading Taiwanese machine manufacturer under the brand "YCM", gave an interesting interview about the matter:

"Micron accuracy is not too difficult. But the key is to maintain that precision to be exact."

In addition to the machine, there are also other factors that affect work accuracy, such as working environment and tools that are used. He stressed that "I can't personally answer how many companies can manufacture machines with micron-level precision. But I'm sure that if it's a machine for mold production, there are few companies."

Stability = Accuracy

Mr. Rick Chen made it clear that the most important thing for the machine’s precision is its stability. If the machine is not installed securely, then it will not be able to work as accurately as needed. With this in mind, YCM designs its machines to be secure and stable as first priority.

Machine Base

YCM designs, casts and manufactures machine bases itself. The base of the machine will be exposed to the sun and rain for months for the parts to be unchanged before processing. Therefore, the YCM machine has a long service life. Over time, the machines of YCM remain stable and able to produce more accurate workpieces for longer.

Spindle

Another important factor is the spindle, which is considered the heart of the machine that affects the precision a lot. When the spindle rotates at high speed, heat from working can make the spindle expand and cause discrepancies. YCM uses ceramic bearing in the spindle, which is a machine component that results in low run-out and not expanding at higher temperatures. There is also a cooling system to maintain the temperature of the spindle and other components that are designed to make the machine to have stability and less vibration.

YCM gathers years of accumulated experience and customer feedback as information to continually develop its own spindles. This sets YCM apart from most Taiwanese manufacturers that choose to buy spindles instead of manufacturing their own spindles.

"At YCM, we have a clear target group. We focus on the market segments that need high-precision machines for the automotive, molding and medical device industries. So, we are dedicated to design and manufacture machines according to the needs of use. By using machine base parts and developing our own spindle technology, we are confident that the YCM machines can operate in micron resolution."

YCM Vertical Machining Center NSV Series - NSV 106AMS

“NSV 106AMS” Vertical Machining Center

This special machine that YCM designs and manufactures for milling a fine mold has a base of 30% wider and has a weight of up to 10% heavier than machines of the same model. It uses a controller with 1 ms processing speed per block (block processing time = 1ms) as well as reading 400 commands in advance (400 blocks look ahead), with 15,000 spindle revolutions per minute (option). When a linear scale feed back is inserted, this machine is ready to operate at micron level.

Testing NSV 106AMS

To ensure that this machine is ready to work at the micron level, Mr. Siraset Tainmai, Senior Sales Manager at HSM Machinery, a YCM distributor in Thailand, has tested this model at the company's technical center.

Mr. Siraset Tainmai, Senior Sales Manager - HSM Machinery Co., Ltd.

The test was to mill the workpiece called "Micron You Can Count" by milling the YCM letters on the NAK80 raw material, which is a high-class plastic mold steel that has a hardness value of 40 HRC. The height of each letter must be 2 microns different in sequence, that is, the letter Y, C, and M is 2, 4, and 6 microns high, respectively.

With this difficult requirement, there must be good preparation before starting the milling:

- Warm up the spindle at the actual operating speed of 8,000 rpm for 30 minutes.

- Measure tool both in length and diameter.

- Measure the workpiece with a touch probe.

- Install an oil-mist cutting system to help chip flow from cutting.

During the actual milling, it is equally important to control the temperature to be constant and to take care of other factors such as checking the oil level of the oil-mist cutting system and preventing it from depletion.

The results show that the machine can be controlled with an error of no more than 0.5 micron. It can be observed from the “YCM” on the "Micron You Can Count" workpiece that Y is less clear than C and C is less clear than M.