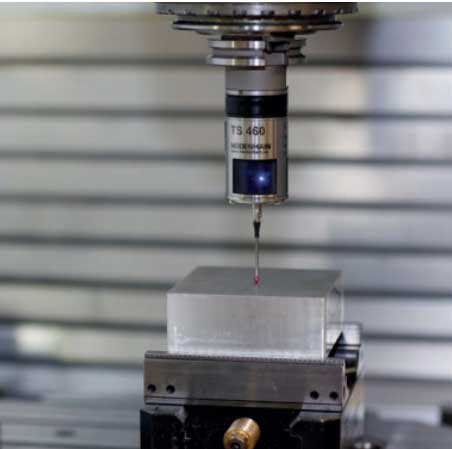

The TS touch probes from HEIDENHAIN help you perform setup, measuring, and inspection functions directly on the machine tool.

Touch probes from HEIDENHAIN are designed for use on machine tools, particularly milling machines and machining centers. Touch probes help reduce setup times, increase machine usage time, and improve the dimensional accuracy of the finished workpieces. Setup, measuring, and monitoring functions can be performed manually or in conjunction with most CNC controls can be controlled by a program.

The TS workpiece touch probes from HEIDENHAIN help you perform setup, measuring, and inspection functions directly on the machine tool.

The stylus of a TS touch trigger probe is deflected upon contact with a workpiece surface. In that instant, the TS generates a trigger signal that is transmitted to the control either over a cable or by an infrared or radio signal. The control simultaneously saves the actual position values as measured by the machine axis encoders and uses this information for further

processing.

Workpiece measurement

HEIDENHAIN offers TS triggering touch probes for workpiece measurement right on the machine. The touch probes are inserted into the tool holder either manually or by the tool changer. Depending on the probing functions of the NC control, they can automatically or manually perform the following:

- Workpiece alignment

- Preset setting

- Workpiece measurement

- Digitizing or inspecting 3D surface

Highly effective and accurate

HEIDENHAIN has been developing and manufacturing touch probes for workpiece and tool measurement on machine tools for over 35 years now. It has set standards, for example, with

- its wear-free optical sensor

- its integrated flushers/blowers for cleaning the measuring point with compressed air or coolant lubricant

- its SE 540 transceiver, which is capable of being fully integrated into the spindle housing,

- its collision protection for the TS 460, and

- its EnDat interface for the TS 460, TS 760, and TT 460 touch probes.

Wear-Free Optical Sensor

Because the optical sensor is free of wear, it is able to provide the specified probing repeatability even after a large number of probe measurements (over 50 million switching cycles). This means that touch probes from HEIDENHAIN are also excellently suited for grinding machines. The optical sensor features an optimized lens system and an integrated preamplifier for stable output signals.

Time savings and increased performance

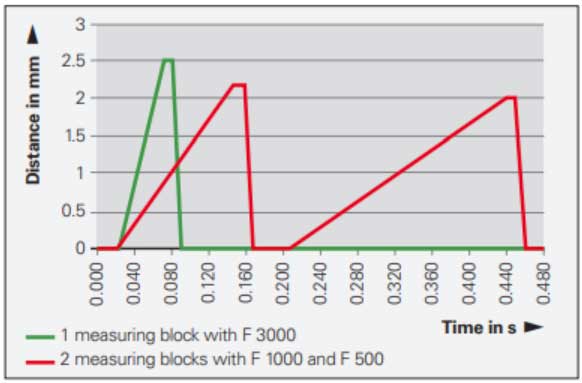

The high probe repeatability of typically 2 σ < 0.5 µm enables setting up and calibration in just one measuring block with the TS 760. Not only can the second measuring block be omitted, but touch probes from HEIDENHAIN also permit high probing speeds at a consistent level of quality.

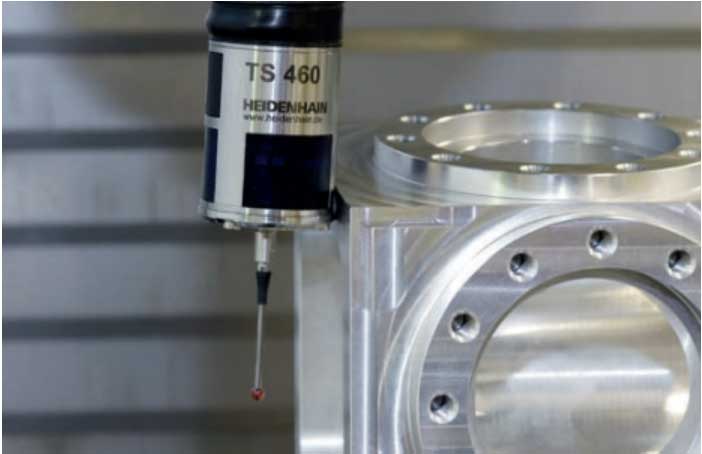

Mechanical Collision protection and thermal decoupling (option with TS 460)

Collision protection and thermal decoupling (option for TS 460) Collision protection is a major topic at HEIDENHAIN. The touch probes feature a sizable deflection path and offer additional safety through rated break points in the stylus and in the connecting pin for the probe contact. For expanded collision protection, including for the touch probe housing of the TS 460, HEIDENHAIN offers an optional mechanical adapter between the touch probe and the taper shank. In the event of a light collision against a fixture or workpiece, the touch probe is capable of yielding to absorb the shock. An integrated switch simultaneously deactivates the ready signal, and the control stops the machine.

Furthermore, the collision protection adapter functions as a thermal decoupler, which protects the touch probe from being heated by the spindle.

Selection guide for TS workpiece touch probes

HEIDENHAIN touch probes are available in various versions for the measurement of workpieces on machining centers, milling, drilling, and boring machines, as well as on CNC lathes:

Touch probes with wireless signal transmission for machines equipped with automatic tool changers:

- TS 460: universal touch probe for radio and infrared transmission, featuring compact dimensions

- TS 642: infrared transmission, activation by switch in the taper shank, and compatibility with previous generations of touch probes

- TS 760: high probing accuracy and repeatability, low probing force, featuring radio and infrared transmission

Touch probes with cable-bound signal transmission for machines with manual tool changing, as well as for grinding machines and lathes: TS 150/TS 750: high probing accuracy (TS 750), with axial or radial cable connection on its base TS 260: axial or radial cable connection

#HEIDENHAIN #TouchProbes #measurement #inspection #Mreport #onlinecontent

Source : HEIDENHAIN (THAILAND) LTD.