A.I. Technology Elevates Digital and Automation, Pioneers Green Manufacturing Initiatives

President of A.I. Technology shares valuable insights about Digital and Automation, the crucial keys to Green Manufacturing.

Mr. Kulchoke Popattanachai, President and CEO of A.I. Group and A.I.Technology Co., Ltd., a leading Thai manufacturer and designer of automated machinery and cutting-edge automation solutions, discusses the pivotal role of Digital and Automation in driving Green Manufacturing.

Perspective on Digital Transformation in the Thai Industrial Sector

President Kulchoke emphasizes the clear emergence and ongoing progress of Digital Transformation, especially during the COVID-19 period, which led to expanded e-commerce and delivery services shift naturally for survival.

The government's push is evident through the Eastern Economic Corridor (EEC) initiative, while the private sector heavily invests in digital, particularly in marketing leveraging Big Data. The industrial sector is heading towards Industry 4.0, utilizing both internal and external Big Data for analysis and planning across various aspects, from consumer behavior analysis, product development, production planning, and machine control, to enhancing production efficiency and quality.

Why Automation, How, and Who Should Implement It

The Thai industrial landscape is undergoing a clear transformation. Presently, automation needs span across various industries, including food, paper, fertilizers, and others, extending beyond just the automotive sector as in the past. This shift is particularly pronounced in Thailand's export-driven industries, which are highly competitive on the global stage. These industries exhibit a strong inclination towards adopting automation, robotics, and digital technologies.

“The most crucial aspects are the vision of the management, followed by individuals with digital capabilities, which are currently lacking in Thailand. Next comes the issue of finances, as transformation requires investment. The final factor is the existing infrastructure and its components. The significant challenge lies in collaboration among individuals, as resistance may arise when changes occur. Digitalization brings transparency and accelerates various processes, uncovering previously concealed issues, violations of regulations, and corruption. These five factors represent both opportunities and challenges in steering towards digitalization.”

This candid advice is offered to support Thailand's transformation towards digital, as emphasized by Kulchoke.

For the A.I. group of companies, they have invested in elevating the digital skill set of their workforce, making them more proficient. They have harnessed digital tools to enhance work on platforms and linkages between them. Mr. Kulchoke cited Generative AI as a current trend, akin to having a 'global-level consultant,' and encouraged employees to use it extensively. This makes it seem as if there are numerous global-level consultants at their disposal.

The knowledge and experience gained from promoting internal staff development have led to advancements in the business. This has resulted in the development of Robotics and Automation Solutions that enhance efficiency for customers. Starting from processes requiring data, which is analyzed through sensor installation to track various machine operations and record the data. Subsequently, we integrate this extensive data, known as Big Data, with the Industry 4.0 concept, employing technologies like Machine Learning for functions such as analysis, inspection, prediction, and development leading to automation solutions that elevate the efficiency of our customers' factories.

Simultaneously, SME entrepreneurs are seeking state assistance. Mr. Kulchoke emphasizes that it's crucial for entrepreneurs to question whether their products still meet market demands, thus aligning market needs as the guiding principle for business. Competitiveness prompts an emphasis on efficiency enhancement. This could start with something as simple as applying Lean principles and using various digital tools. They might begin with tools like ChatGPT or other straightforward instruments.

“However, even though there's an abundance of free platforms and software, the issue may lie in the limited availability or proficiency of users. This brings us back to the country's challenge of having enough skilled individuals or those with a skill set to address future national needs adequately and promptly,” notes Kulchoke, leaving stakeholders with food for thought.

The A.I. group of companies has collaborated with various public sector and educational institutions, including universities and colleges, that seek to study and gather information about the industrial sector's direction and ongoing initiatives. They have also partnered with educational institutions to develop relevant courses and promote the advancement of personnel in the field of automation.

Perspective on Green Manufacturing

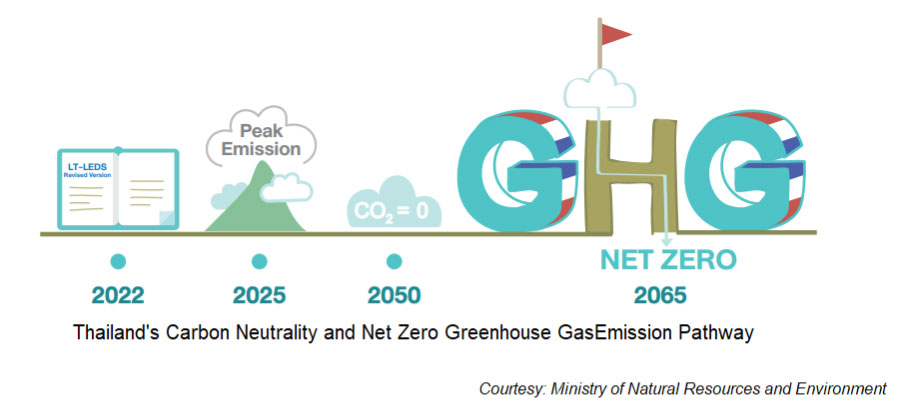

President Kulchoke views Green Manufacturing as another dimension of the ESG concept, which has garnered global investor interest. The industrial sector in Thailand shares responsibility for climate change mitigation. Thailand has announced its commitment to achieving carbon neutrality by 2050 and net-zero greenhouse gas emissions by 2065. Currently, the nation is in the process of drafting legislation regarding climate change.

Currently, Thailand's readiness is still at a low level. Heavy reliance on fossil fuels for energy production remains a significant obstacle to achieving carbon neutrality. The private sector is grappling with this new paradigm, a global trend. Many questions arise, such as how many trees we need to plant to offset carbon emissions, what carbon credits entail, and how carbon credit trading works.

The process of adopting alternative materials and renewable energy, recycling, and changing production processes and technologies for carbon reduction presents various options. Importantly, these technologies and processes are still new and come at a high cost, signifying that "the more you do, the more expensive it becomes. Additionally, there is currently a lack of supportive legislation, which makes people uncomfortable in terms of costs.

This brings us to the concept of 'EPR' (Extended Producer Responsibility), which expands the environmental responsibility of producers to cover the entire lifecycle of products and packaging (from design, production to environmentally-friendly packaging management).

“In the past, we were familiar with CSR, but today, if CSR is just greenwashing, it doesn't solve the problem. Because it has to lead to the recycling loop in the end. Everyone has to genuinely do it,” said President Kulchoke.

Ultimately, legislation will play a crucial role in driving widespread environmentally-friendly practices. Incentives and penalties will dictate responses from companies, including handling accountability avoidance that may occur, as some may try to circumvent compliance.

Transitioning towards this sustainable practice is a global endeavor. Therefore, countries that fail to adapt will face economic disadvantages and trade restrictions, as non-compliant products may face higher carbon taxes.

However, in the realm of Net Zero Emissions, there are 'opportunities' for Thailand. With a significant number of agricultural practitioners, there is potential for carbon credit trading. Additionally, those with innovative technologies and business ideas aligned with these directions can find a niche.

Overview of A.I. group of companies and Future Adaptation

President Kulchoke reiterates that Digital and Automation make Green Manufacturing more accessible, enabling reduced energy and raw material usage, lower emissions, and increased production yields. It facilitates efficient planning across various aspects.

Business Overview for this Year: The AI Group has implemented a strategy to expand its business through new target groups, coupled with upskilling its workforce to be more adept and utilizing automation and digital technologies extensively. It's anticipated that this will lead to a growth of up to 20% compared to 2019, a period pre-dating the COVID-19 outbreak.

Here is the progress of four companies under the AI Group:

1. A.I. Technology, specializing in the design and production of special machine and automation solutions, has developed a range of applications that support various automation tasks. These solutions address situations where labour savings are required while simultaneously increasing productivity. Examples include Robot Palletizing, AGV, ASRS, and WMS (Warehouse Management System).

The target groups span both automotive and non-automotive industries. This year, there has been a significant shift towards investing in automation, especially in the export products group, such as fertilizers, food, and paper. As for the automotive sector, investments are still awaiting the adoption of EVs and other factors.

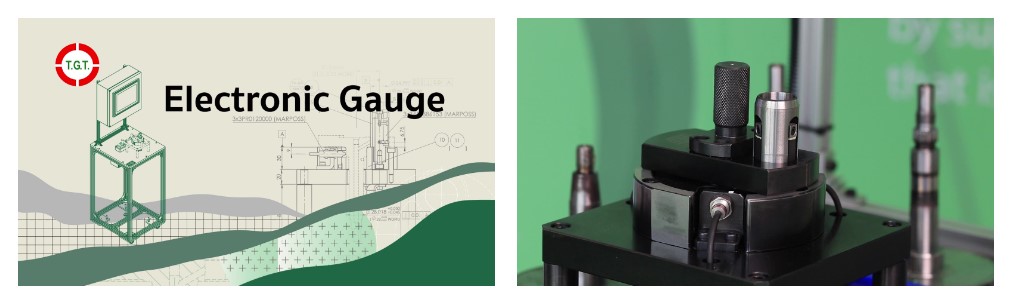

2. Tokai Gauge, which manufactures industrial gauges for measurements, has developed a Digital Gauge capable of measuring various parameters at multiple points in one unit. It also records data piece by piece, contributing to statistics that can be analyzed for future production planning.

3. A.I. Foundry, originally involved in casting, particularly in the automotive industry undergoing transformation. Despite changes in the automotive industry, new vehicle models have been introduced, resulting in orders for casting components like camshaft, brake systems, and gear systems. The company has developed high-quality casting technology for materials like FCD700 grade iron, which reduces energy consumption, material usage, and waste.

4. A.I. Innovative Plus, formerly focused on producing simple kitchenware products without innovation, has adapted to the Industry 4.0 and Digitalization era, leading to the development of new products for the medical and health industry. They've combined their knowledge of plastics with electronics, creating products like the Ionizer developed in collaboration with the university and introduced during the COVID-19 pandemic. This product incorporates a plastic casing and an electronic circuit to create a negative charge when in contact with the human body. This helps reduce the risk of exposure to contaminated air. This product addresses concerns about PM2.5, making it suitable for health-conscious individuals and patients with respiratory

Through collaboration across all sectors, integrating digitalization and automation into production processes will lead to efficient Green Manufacturing. This results in reduced energy and resource consumption, minimized waste, and increased production yields. Consequently, the Thai industrial sector has a strong opportunity for development and adaptation to a resilient future.