Automakers Accelerate Development of Solid-State Battery, Eyeing Competitive Edge in EV Market.

Accelerating All-Solid-State Battery Development to Improve EV Competitiveness with Long-Range Cruising and Low Cost.

Japan, March 30, 2024 - Interest in all-solid-state batteries is increasing as the electrification of vehicles, including electric vehicles (EVs), progresses toward carbon neutrality (CN), aiming for virtually zero greenhouse gas emissions. Research and development are advancing globally as key solutions to EV challenges, such as extending cruising range, shortening charging time, and reducing costs. The movement surrounding "dream batteries" has become more active.

NISSAN:

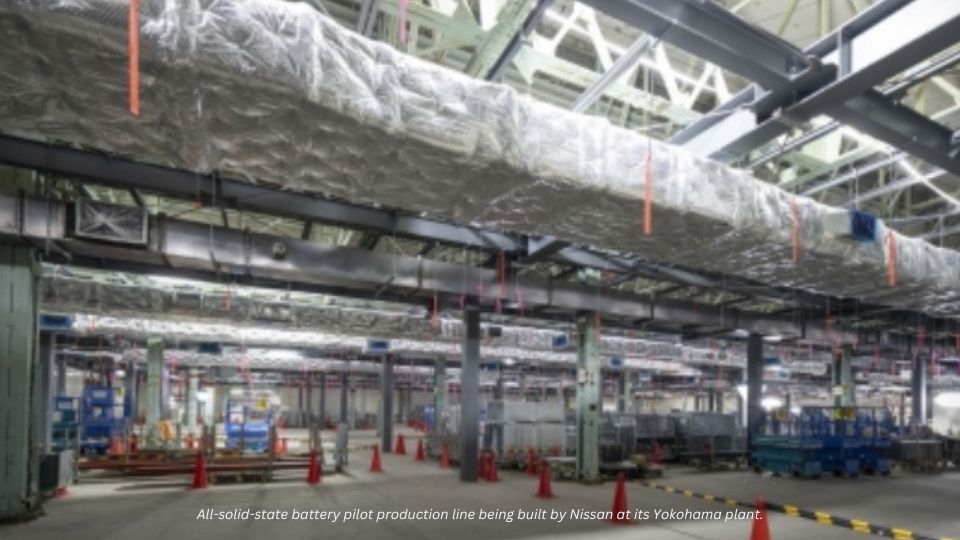

Nissan Motor Co., Ltd., is constructing a pilot production line for all-solid-state batteries at its Yokohama Plant (Kanagawa Ward, Yokohama City). They are renovating an existing factory that manufactures engines and motors and proceeding with the construction of a clean room and ancillary equipment. The company aims to install production equipment and start operations in March 2025.

The pilot production line, currently under construction, is 135 meters long by 75 meters wide, with a floor area of approximately 10,000 square meters. It consists of the following steps: electrode, cell, module/pack, and chemical formation. The investment amount has not been disclosed, but the annual production capacity is planned to be a maximum of just under 100 megawatts (MW), equivalent to 2,000 cars. Around 200 people will work on research and development on the same line.

Nissan will proceed with the development of products and production technology on the same line and will begin public road tests with prototype vehicles in FY2026. The company aims to increase production capacity and productivity and launch new EVs equipped with all-solid-state batteries from FY2028, as outlined in the long-term vision “Nissan Ambition 2030.” Vice President Hideyuki Sakamoto said, “We have been involved in the design and production technology of electric vehicles for many years, and we believe that all-solid-state batteries are the ultimate goal.” He added, “We hope to improve the competitiveness of electric vehicles by developing innovative production technology and applying mass production. We will make dramatic improvements.”

HONDA:

Honda will invest 43 billion yen to launch a demonstration line in Sakura City, Tochigi Prefecture, to accelerate the development of its all-solid-state batteries and bring the technology into its own hands. The company aims to use it in next-generation EVs to be introduced in the late 2020s. They will promote electrification globally and aim for a 100% global sales ratio for EVs and fuel cell vehicles (FCVs) by 2040.

TOYOTA:

Toyota Motor Corporation has set a goal of equipping EVs with solid-state batteries as early as 2027 or 2028. The company selected Idemitsu Kosan as its partner, and the two companies set up a special task force consisting of several dozen people. They will work on developing mass production technology, establishing a production system, and building a supply chain. The company plans to develop and mass-produce all-solid-state batteries that are highly competitive and easy to popularize, thereby increasing the market competitiveness of EVs.

Toyota and Idemitsu announced their collaboration on all-solid-state batteries last October.

(Toyota President Tsuneharu Sato and Idemitsu President Shunichi Kito, shaking hands).

Toyota and Idemitsu are aiming for an all-solid-state battery that has a range per volume that is 2.4 times greater than the lithium-ion batteries (LiBs) used in current EVs. Toyota President Tsuneharu Sato said, “The key to changing the future of cars is collaboration between the automobile and energy industries. We will combine the strengths of both companies to mass-produce all-solid-state batteries and realize innovation from Japan.”

All-solid-state battery that Toyota aims to use in EVs.

High Expectations for a Game Changer:

All-solid-state batteries are characterized by the fact that the electrolyte is solid rather than liquid. Their energy density and power density are superior to LiBs, and their internal resistance is low, making them suitable for rapid charging. Since there is no electrolyte, they are chemically stable and have excellent durability, reliability, and safety. This dramatically improves battery characteristics, such as shortening EV charging time and extending cruising distance, and improves the functionality and marketability of the vehicle itself. Expectations are high that it will be a "game changer" that will accelerate the spread of EVs. Major vehicle manufacturers in Japan, Europe, and the United States have announced plans for mass production, and research is progressing particularly in China, where the new energy vehicle (NEV) market is currently expanding worldwide.

However, for battery quality control, a dry environment is required to prevent moisture from entering. Therefore, dew point control is essential in the manufacturing environment, and it is difficult to achieve the manufacturing environment and conditions in a mass production factory. Global Data, a British research company, has a cautious outlook on the expansion of the all-solid-state battery market, stating that as of 2030, the capacity of global all-solid-state batteries will be approximately 2.3 gigawatt hours (GWh), which is the total battery capacity. The market share is estimated to be 0.08% compared to 2,743.8 GWh.

Since its introduction in 2027, safety has become an issue for widespread use. Mr. Shoji Kinoshita, Chief Consultant, MarkLines Consulting Division, stated, "All-solid-state batteries are expected to solve EV issues such as cruising range and charging time. EVs are quiet and powerful. If the price of all-solid-state batteries settles down to an appropriate level and becomes widespread, the times will change."

There are different types of all-solid-state batteries, but the most common are those that use sulfides. The challenge is ensuring safety. There have been incidents of fires occurring with current LiBs. If a battery catches fire, it is difficult to extinguish it. Each company is carefully developing all-solid-state batteries for use in general cars.

Completed car manufacturers and battery manufacturers around the world are competing to develop all-solid-state batteries. Although development is progressing at the demonstration level, it will probably take some time before mass production and widespread use. The EV market as a whole is also changing, and the tide is changing. It will be introduced in 2027-2028, but it is unlikely that it will be replaced immediately.