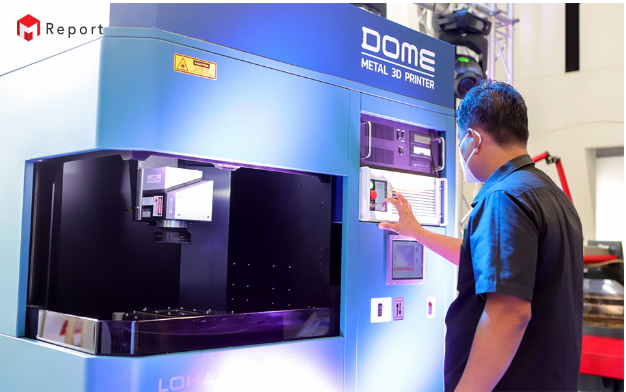

Get to Know DOME LOHA 664T, Thailand's First Metal 3D Printer

The 3D printing technology has been rapidly growing. Recently, Thailand introduced its first metal 3D printer, the "DOME LOHA 664T," developed, designed, and produced entirely by Thai engineers, marking a significant milestone in Thailand's 3D printing technology that is set to revolutionize the country's metal industry.

“DOME LOHA 664T” is the brainchild of Dome Nuchanong, founder and CEO of Dome Corporation Limited. He shared that the inspiration behind developing the metal 3D printer came from the high prices of foreign printers, starting at a staggering 10 million baht. This high cost posed a barrier to investment, product development, and competitiveness for Thai SMEs. The metal 3D printer is expected to accelerate the design and development of new products, making it much faster than before. With fierce competition in the market, being late to the game can lead to significant losses.

"My inspiration came from customers’ questions. We have been manufacturing FDM 3D printers, which print in plastic, for 8 years. A common question from customers was whether we could print in metal. After discussing with customers, we found that foreign machines were prohibitively expensive, not to mention the high cost of each printing session. This inspired us to create a more affordable machine," said Dome.

Challenges in the Current 3D Metal Printing Market

Dome Nuchanong views metal 3D printers as a relatively new technology for Thais, with complex designs among different brands. Unlike cars, where each brand has similar designs, repairing metal 3D printers is challenging, requiring highly skilled technicians trained by the manufacturers. In some cases, technicians from the manufacturers' countries must be imported for repairs, incurring high costs.

Challenges and Opportunities in Development

Dome Nuchanong highlighted that the most challenging aspect of R&D is investment, as it carries high risks unlike buying and selling products. Finding Thai investors who understand this has been extremely difficult. However, successful R&D results in higher and more sustainable returns than simple trading. Therefore, many countries provide substantial government funding for innovation and technology development. This is also a significant challenge for Thais who want to innovate in Thailand, as they must compete with innovations from foreign companies that receive government support.

In conclusion, Dome emphasized that developing new technologies is crucial for the future. Going forward, contracting manufacturing or trading will become increasingly challenging. Every country aims to bring production back to its homeland. However, with your technology, you can set your price because the whole world is your market, not just Thailand. For those who want to develop their technology, he advises self-reflection on their patience levels, as patience is something that cannot be found elsewhere, unlike knowledge or capital, which can be acquired.

DOME LOHA 664T Metal 3D Printer

Highlights of the DOME LOHA 664T Metal 3D Printer

The DOME LOHA 664T metal 3D printer stands out in several aspects. It supports workpieces up to 6 x 6 x 4 cm and can currently print in four materials: Inconel, Steel, Stainless Steel, and Titanium. It has also registered a petty patent for "The base plate is 3D printed from metal powder using a low-energy laser" (SLM quick stick base technique). This feature ensures successful printing every time.

Additionally, there are many other advantages, as identified by Dome Nuchanong:

- Affordable prices for Thai SMEs, allow them to innovate and compete in the global market with pride.

- 100% after-sales service as it is designed and manufactured in Thailand, ensuring sufficient knowledge to provide consultations to customers in both hardware and software aspects, guaranteeing valuable use of the machine.

- Can print various types of materials, from high-engineering materials like Inconel to medical-grade materials like Titanium Grade 23.

- Easy to use, with an ergonomics design that includes doors that slide open in both directions at the bottom, making loading and unloading of workpieces and printing materials easy.

- The chamber size for controlling shielding gas during printing is small, significantly reducing Shielding gas consumption.

- Features a Powder Homogenization System (PHS) to ensure consistent material density throughout the powder bed, crucial for a high-quality surface finish. Inconsistent density can lead to missing parts of the surface finish. The PHS system ensures uniform density throughout the bed, resulting in smooth and fine surface finishes.

“In the future, the DOME LOHA 664T will be developed to expand the size of the printing bed to accommodate larger prints, such as aircraft components,” Dome said.

View on the Role of Thais in Technology Development

Dome Nuchanong believes that Thailand has many talented individuals with a long history of technology development. Previously, there were Thai computer brands like Thaworn and Thai electrical appliance brands like Tanin. Currently, many Thai brands do not use the Thai name but have been extremely successful, which is something to be proud of. However, to advance technology, there must be a starting point, which is capital. This capital undoubtedly comes from sales. Therefore, he invites Thais to use Thai products more to give developers the strength to innovate and compete in the global market, and to attract investment for future development in the country.

Furthermore, he believes that the development of metal 3D printing technology will bring beneficial changes in various areas. For example, it will help the aviation industry reduce fuel costs significantly by producing lighter parts. Additionally, the quality of life for humans will improve as the production of prosthetics becomes easier, faster, and cheaper. The cooling systems in various machines will become smaller and more efficient, and products will undergo rapid and frequent model changes, eliminating the problem of old machine parts. This is because new parts can be printed whenever needed.

Finally, Dome Nuchanong would like the government to implement measures to promote the marketing of technological products, which represent the hard power of Thailand, to enhance its competitiveness in the global market. These hard power products will strengthen and sustain the Thai economy, as they are difficult to imitate and have a product life cycle that lasts for decades.

DOME LOHA 664T metal 3D printer was officially launched

at the Machine Tech Open House 2024 on March 8th.

For those interested in the DOME LOHA 664T metal 3D printer, please contact Machine Tech Company Limited, call 02 726 7191-5.