Toyota Strengthens Japanese Manufacturing: New Vehicle Plant in 14 Years Secures 3 Million-Vehicle Capacity and Supply Chain

Toyota Builds First New Vehicle Factory in Japan in 14 Years

Toyota Motor Corporation is reinforcing Japanese manufacturing with the construction of a new vehicle factory in its home city of Toyoda, Aichi Prefecture — the first in Japan in 14 years. As existing factories age, production is expected to be gradually transferred to the new facility while older plants are repaired and modernized. Toyota remains a key contributor to the Japanese economy, supporting employment and earning foreign currency. The company is also exploring advanced factory operations, including automation.

| Advertisement | |

Modernizing Aging Factories While Maintaining Capacity

This new factory is the first since Central Motor’s Miyagi Plant (now Toyoda Motor East Japan) in 2011. It will be located near the Teiho Plant, which produces machinery and equipment, and is expected to start operations in the early 2030s.

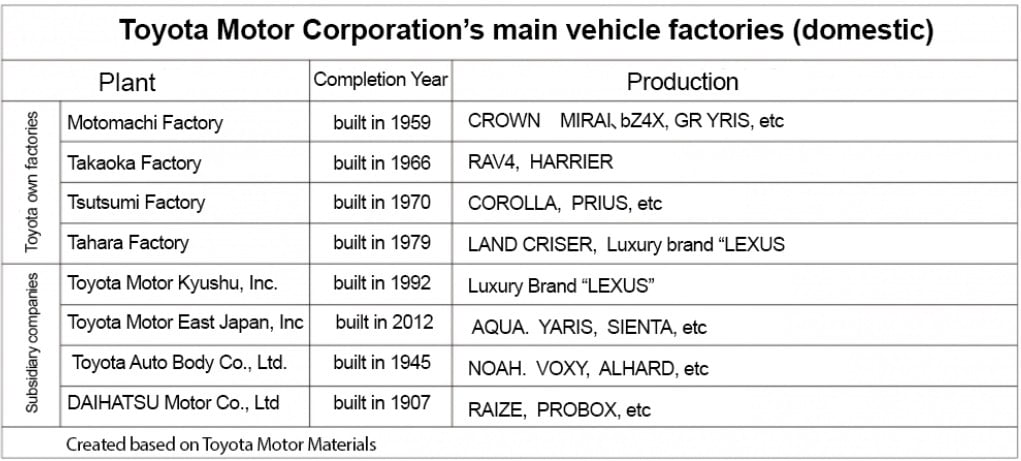

Toyota currently operates 14 factories and 28 production lines in Japan. Some facilities, such as the Motomachi, Takaoka, and Tsutsumi factories, have been operating for over 50 years. Accounting Division Chief Azuma Takanori notes, “We will improve our system while updating aging facilities to preserve Japan’s manufacturing base and create a place where solid manufacturing can be carried out while exploring new ways of working.”

Expanding Investments Overseas While Focusing on Domestic Production

Recently, Toyota has made large-scale investments abroad, including an automotive battery plant in North Carolina, EV production at the Princeton Plant in Indiana, and a new Lexus factory in Jinshan, Shanghai, China. Domestic partners have expressed appreciation for the focus on Japanese production, highlighting its significance for local industries.

Maintaining the “3 Million Vehicles” Domestic Production System

Toyota has emphasized the importance of maintaining a domestic production system capable of producing 3 million vehicles annually. Despite temporary drops during 2020–2022 due to COVID-19 and semiconductor shortages, Toyota has largely sustained this target. The company’s robust domestic supply chain enables both volume and profitability through close collaboration with business partners on-site.

Preparing a Factory of the Future

Preparations for the new factory were highlighted at Toyota’s February 2025 annual policy briefing. President Koji Sato emphasized renewing aging buildings and equipment to ensure a safe and productive workplace. The factory will focus on people-centered production rather than fully unmanned operations, reducing production steps and lead times, optimizing logistics, and consolidating supply products for cost efficiency.

Responding to Challenges in the Japanese Manufacturing Environment

According to the Ministry of Economy, Trade, and Industry, the number and size of new factories in Japan have declined to one-third to one-quarter of 1989 levels. The manufacturing environment faces multiple pressures, including geopolitical tensions, supply chain disruptions, weak yen import costs, and a shrinking workforce.

Local Factories Support Jobs and Regional Economies

By building a new domestic factory, Toyota not only safeguards its production system but also supports local employment and the regional economy. The move is closely watched to see whether it will influence other companies in Japan and beyond.

Source: Nikkan Kogyo Shimbun