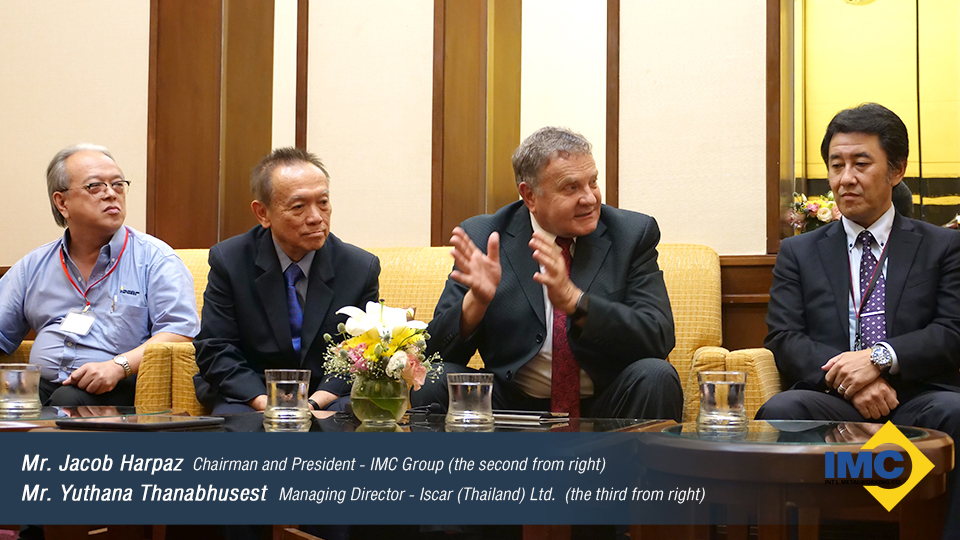

Advice on Thai Industries from Chairman and President - IMC Group

June 19, 2019 – Mr. Jacob Harpaz, Chairman and President of IMC Group, came to Thailand to provide a speech on “Innovation of Global Metalworking Industry and the Importance of Industry 4.0” as well as to present new products of ISCAR to more than 400 Thai industrialists attending the seminar, including the interview with industrial news reporter from M Report in various aspects at Novotel Bangkok Suvarnabhumi Airport.

Who is IMC Group?

International Metalworking Companies or IMC Group is the world's second largest metalworking company consisting of 13 companies, 130 subsidiaries in 60 countries around the world with well-rounded strength and it is a company under the investment of Berkshire Hathaway Inc of Mr. Warren Buffett, the world’s most famous investor.

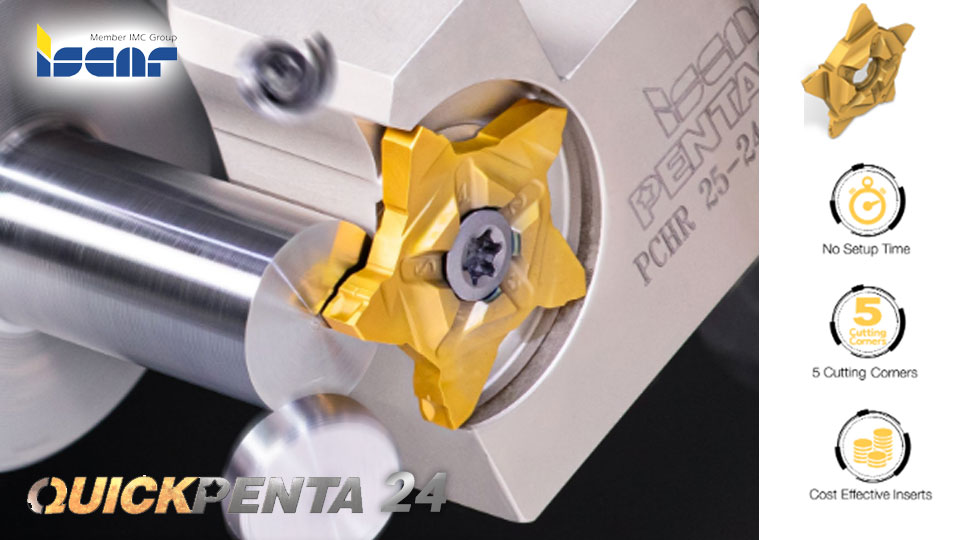

At present, IMC Group’s market share is ranked No. 1 in Thailand for cutting tools products, carbide inserts, carbide endmills, and other cutting tools covering most metal cutting applications. In addition, the Company provides engineering and manufacturing solutions to major industries such as automotive, aerospace, railway, mold and die, etc., leading to a variety of innovative products to serve the best of each industry. This makes IMC Group be the world’s leader with ISCAR as one of the flagships of IMC Group.

M Report: What do you think about the electric vehicle industry in the future?

Mr. Harpaz: “At present, the EV market has been worldwide talk-of-the-town topic and EV market is definitely growing. However, from my experience meet up with industrialists around the world, I’ve found that there are huge amounts of investment in the automotive industry on turbocharger which reduces the size of the engine, increases its performance, provides energy saving ability, and is eco-friendly.

Despite the drastic growth of the EV, the growth is in the realm of specific usage such as in the city where there is serious pollution management. I’d like to say that there is another kind of automobile which has a high tendency of growth, namely, hybrid automobile. It is the automobile with the high efficiency of energy consumption, energy saving, and support of worldwide government’s privilege program”

M Report: What are the suggestions for auto part manufacturers?

Mr. Harpaz: “In my opinion, the most important thing for the auto part manufacturers is the understanding of changes in metal works which are stepping into product manufacturing process with better quality such as precision casting, precision forging, etc. The manufacturers must prepare themselves for higher numbers of production volume, especially when it comes to competitions with manufacturers with high production capacity, for instance, from China. Nowadays, Thai manufacturers try to focus and taking an effort to reduce production cost. However, if Thailand wants to remain its position as the manufacturing hub of auto parts, the Thai manufacturers must develop its technology. In this era of continuity development of technology, the sole emphasis on the reduction of production cost cannot help them to match up with others in many aspects.

IMC Group’s products have been developed in accordance with the now-trend and the future-trend in 10 years ahead. The products are faster and more precise. Whether they are machine tools or other global technologies, I believe that they provide only a slight impact on the automobile industry. It is because most of the people do not buy EV and general cars are still necessary.

I hope that Thai manufacturers will have a better understanding on Industry 4.0 as what it is. It is not just a slogan, but it is an actual change. You cannot insist on working with existing technology without developing your skills”

M Report: What is your view toward Thai industries?

Mr. Harpaz: “I can see a drastic development since the first time that I entered the market for more than 35 years. Thailand’s automotive industry is very strong. There is no doubt why Japanese manufacturers see Thailand as the hub of automotive manufacturing outside Japan. Of course, there are ups and downs in the market. For example, in this year, the market has been affected by the trade war between China and the US. Other countries such as Japan, South Korea, have also been affected by the situation. However, I believe that in the future, the Thai industries will be definitely improved.”

M Report: Do you have any suggestion for Thai industries?

Mr. Harpaz: “I still want to see the Thai people to produce their own products, building their reputation. There should be products, stamped with ‘Made in Thailand’ as a sign of quality product, exported around the world. Once this is executed, I believe that everyone will receive the worthiness and be proud of the brand Made in Thailand.”

In addition, Mr. Harpaz added that IMC Group had a plan to establish a plant in Thailand to produce IMC quality and standardized products soon. This is good news for Thailand in terms of economy and for Thai industries to rapidly keep pace with metalworking technology.