C.C.S. Group Expects a Minimum Growth 100% in Next 5 Years

C.C.S. Group is known to be one of the leading parts manufacturing companies with highly advanced machinery as well as its production and assembly capacity for Tier 1 and Tier 2 aerospace groups, such as UTC, MEGGITT, MOOG Aircrafts, AEROCONTROLEX, EATON and TRIUMPH. These companies are suppliers for Boeing, Airbus and Bombardier. Mr. Ketan Pole, the C.C.S. Group’s chief executive officer (CEO) revealed to the M Report with confidence that its growth by 100% is expected in the next five years. Let us look at the reason why he believes accordingly.

C.C.S. Group Business Profile

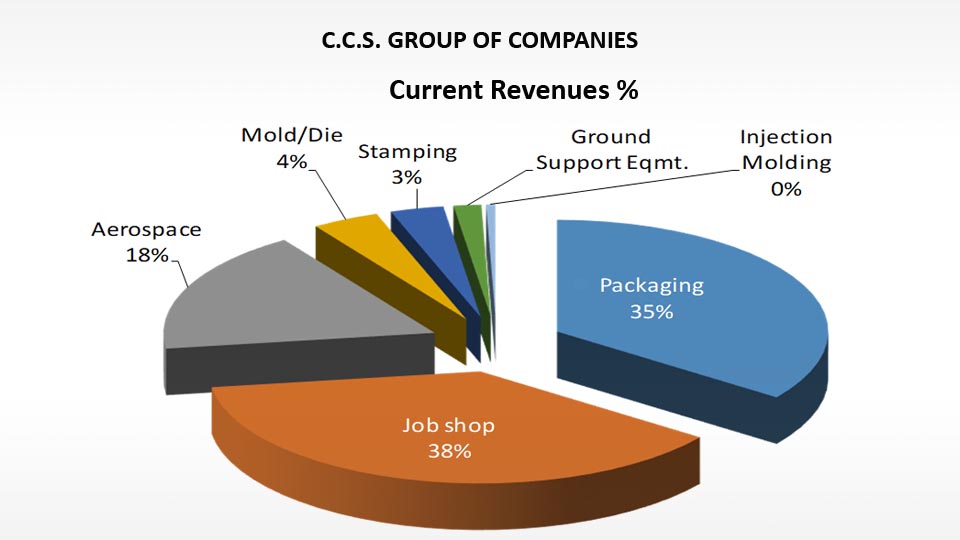

C.C.S. is one of the world-class “one stop manufacturing” companies with over 300 CNC machines and more than 1,000 employees. Non-aerospace units provide build to print manufacturing services for end users such as Minebea, YAMAHA, P&G Gillette USA and INA Schaeffler. Over 70% of its products are exported to USA and Europe.

With its capacity to produce a variety of products, C.C.S. can provide one-off, small batch and mass production services that meet international standards with the implementation of SAP/ERP systems for production quality control. Its production consists of several following divisions.

- Job Shop : ISO 9001 certified for build to print manufacturing for all industries that require precision of parts’ specifications: bearing industry, shaving blade industry, electronics industry, medical and health industry, spare parts for tools and mold, oil and natural gas industry and jigs and fixtures for all industries.

- Aerospace : AS9100 and NADCAP certified as direct OEM of parts and components production for aerospace worldwide, with effective CNC machinery used in production as well as other special procedures in the manufacturing factory.

- Mold and Die : ISO 9001 certified for “design, build and assembly” services, metal stamping tools, plastic injection mold and rubber mold.

- Metal Stamping Production : large and small orders of metal stamping products.

- Metal Sheet Production : cutting with water jet, laser cutting tools, drilling with the CNC Turret punching, shearing and cutting and bending with the press brake tools.

- Plastic Injection Production : large and small orders of plastic injection products.

- Plastic Vacuum Thermoforming : design, build and produce plastic vacuum thermoforming tools.

- Aviation Ground Support Equipment : design, produce and distribute aviation ground support equipment.

- NADCAP certified for non-destructive testing (NDT)

- ISO / IEC 17025 compatibility certification service

Business Diversity

With his vision and strategic direction, Mr. Booncharoen ManoBoorachailert was a sole founder of the C.C.S. Group in 1989. He had merely one machine and one customer, “Minebea”. Later in 1997, I, Ketan Pole joined his business, with my expertise in technical and administrative aspects.

Mr. Booncharoen’s philosophy is to compare C.C.S. as “a 20-legged table.” That is to say, if a few of its legs were broken, it would not collapse. We have used this principle to attempt to increase our customers’ capacity; simultaneously, we have regularly had more customers as well as new machines yearly.

C.C.S. not only aims at working hard, but also working smart. Especially, after we had adopted the SAP / ERP system, which is the international work standards, C.C.S. has grown so exponentially that it became the first Thai company that produced and exported Precision parts to USA and Europe. In addition, C.C.S. was the first one in Thailand with AS9100 and NADCAP certification. Despite having implemented the SAP system for only 17 weeks, the company had an opportunity to work for GE.

The key strategy of C.C.S. is to maintain our major business divisions such as job shop, build to print as well as other supporting industries while placing an emphasis on aggressive expansion in aerospace industry. Until now, C.C.S. Group’s profit has increased up to 12 times as much income as that in 1997. Therefore, over the past 5 years, the aerospace business has seen more than 400% growth and we expect more business gains in many years to come.

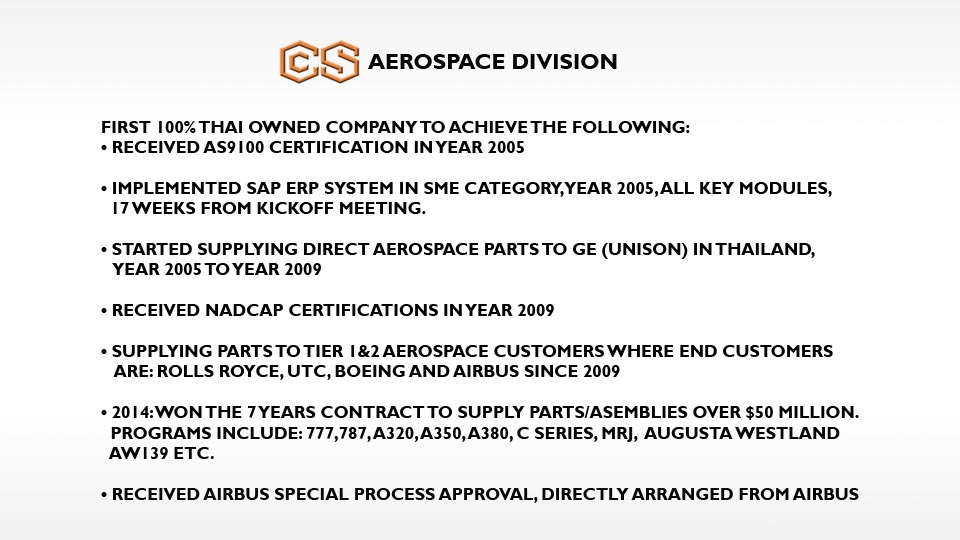

Beginning of C.C.S. and Aerospace Business

My previous work experience involved satellite launching vehicles and motorized rocket manufacturing. In 2005, I submitted a proposal to GE Thailand to supply jigs, fixtures and cutting tools. Our outstanding work led to another chance in the following year to supply aerospace parts directly to GE. We therefore pushed forward with no hesitation to obtain AS9100 and S1000 certification shortly.

C.C.S. Growth in Aerospace Industry

After GE had moved its company out of Thailand in 2009, we developed partnerships with Goodrich, MEGGITT, UTAS, Aerocontrolex Group, EATON, MOOG and Triumph Group. We realized that facilities for special procedures in aerospace parts production in Thailand were necessary. Thus, we decided to utilize them for anodizing, passivation, hard chrome plating, E-Ni plating, paint / primer spraying and other procedures related to non-destructive testing (NDT). We are one of a few Thai companies with NADCAP certification. With this high performance, our aerospace business and exports have grown by more than 400% over the past 5 years.

Key to C.C.S.’ success in Aerospace Business

English is fundamentally essential in the aerospace business as all work-related documents are in English. Consequently, staff members holding major positions ranging from mid to executive levels possess high command of English. In addition, to manage all of our work systems, such as SAP, requires staff to use English. Another most important set of qualifications for those working in the aerospace business is “Passion, Patience and Perseverance". Generally, most people wish to earn high income from business in a short period of time, yet the aerospace business is a long-term type of strategic business that requires a great deal of experience and training. To simply put, it is not an easy step for novices to be familiarized with a number of processes to be in this business.

C.C.S.’ Growth Projection in Aerospace Industry

At present, C.C.S. supplies parts for 777, 787, A320, A350, A380, C Series, MRJ, AW139, and other models. Despite an increase in business gains by 400% in the past 5 years, we expect to double the business growth in the next 5 years. That means we should expect at least 20% growth yearly. In case that we have more opportunities to supply our parts for large projects, our estimated growth will certainly be higher accordingly. This is our marketing strategy: to look for opportunities to grow. The projected target of 100% business growth in the five-year time is therefore possible.

C.C.S.’ Vision on Global Demand of 32,600 Aircrafts by Airbus in Next 20 Years

We are competing with the best cost countries in the aerospace business in spite of our disadvantages since Thailand is not an aviation hub. On the other hand, Thailand is an automotive hub that manufactures car makers such as Toyota, Honda, and others. Thus, neither Boeing and Airbus aircrafts nor Tier 1 automotive parts are manufactured in Thailand. The Thai government focuses on MRO, which is a hub for aircraft maintenance, repair and overhaul and acts as a different business segment from parts manufacturing. Therefore, it does not offer much benefit for Thai entrepreneurs. As an OEM parts manufacturer, our main business competitors are Malaysia, Taiwan, Korea, India, and China. Their governments strongly urge local manufacturing companies to build aerospace parts business cluster.

C.C.S. has a strong belief in organic growth, so we do not support merger and acquisition for our company’s growth.

Challenges for Thai parts manufacturing companies are the following:

- Strong financial support for initial heavy investments

- Focus more on skilled vocational labor than highly educated engineers.

Therefore, to pursue this global demand opportunity, Thailand must have the bargaining and negotiating power by encouraging local parts manufacturing companies to compete with other countries.

Demands for the Thai Government’s Support

- Current promotions should be provided to foreign direct investment (FDI) to mainly focus on MRO and airports. For Thailand’s SME clusters, the focus should be on OEM parts manufacturing.

- Malaysia, Taiwan, Korea, India and China are the main competitors of Thailand’s aerospace manufacturing.

- The Malaysian government helps their local entrepreneurs with initial subsidies for CNC equipment in order for them to start the aerospace business and expand it rapidly. Not only does the government offer them long term low interest rates, but it also attracts Tier1 and Tier 2 manufacturing companies with better promotions to invest in Malaysia.

- The Thai government should benchmark the other countries’ economy for their success. Thailand has fewer than 15 companies with AS9100 certification while Malaysia has over 60 and Singapore has over 100 companies. Why does Thailand excel in automotive business today? Toyota invested here, Honda invested here, and Mercedes invested here. This is why top tiers companies have further developed and SME clusters have also grown.

Future of Thai Aerospace entrepreneurs in the five years’ time

I feel that Thai aerospace parts manufacturing entrepreneurs with international standard certification are projected to have their business expanded by 100% in the next 5 years. There will also be business opportunities for foreign investors in the EEC project, especially the MRO project. Nonetheless, Thai SME entrepreneurs as well as new entrepreneurs with organic growth are unlikely to have the same opportunities unless the government adopts different business policies.